How to use bending machine equipment correctly?

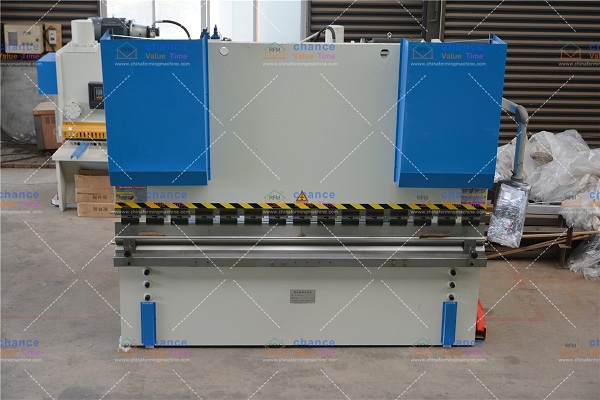

The bending machine includes a bracket, a worktable and a clamping plate. The worktable is placed on the bracket. The worktable is composed of a base and a pressing plate. The base is connected to the clamping plate through a hinge. The base is composed of a seat shell, a coil and a cover plate. In the recess of the seat shell, the top of the recess is covered with a cover plate.

When in use, the coil is energized by a wire, and after being energized, a gravitational force is generated to the pressure plate, thereby realizing the clamping of the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and the workpiece with side walls can be processed.

First, turn on the power of the bending machine, turn on the key switch on the control panel, and then press the oil pump to start, so you can hear the sound of the oil pump rotating.

Second, stroke adjustment, use must pay attention to adjust the stroke, must be tested before bending. It must ensure that there is a gap between the upper die and the lowermost die. Otherwise it will damage the mold Yangcheng Lake hairy crabs and the machine. The adjustment of the stroke also has electric fast adjustment and manual stomach adjustment.

Third, Bending notch selection, generally choose a slot with a width of 8 times the thickness of the plate. If bending a 4mm sheet, a notch of around 32 should be selected.

Fourth, the back gauge adjustment generally has electric fast adjustment and manual fine adjustment, the same method as the shear.

Fifth, step on the foot switch to start the bending. The mold of the CNC bending machine is different from the shearing machine. It can be released at any time. When the foot is released, it stops, and continues to descend on the step. Plastic CNC Bending Machine Mould, Plastic Folding Machine, Plastic Plate CNC Bending Machine Mould, Plastic Sheet Bending Plastic Sheet Bending Directly, No Splicing, No Slotting, No Electrode Needle If it leaks, it will transform manual welding into fully automatic machine operation, which improves quality, improves labor efficiency, reduces labor costs, and greatly shortens the production cycle of products. The automatic plastic bending machine belongs to the electric integrated automatic mechanical equipment.