The rapid change of C Z purlin roll forming machine saves time and material cost. Many profile production plants are very interested in the automatic type change.

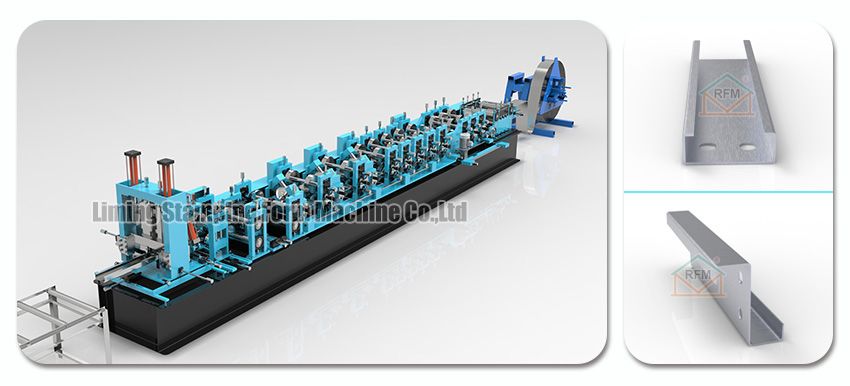

Mr. Kate is a builder of British steel structure factory. In order to produce various types of purlin products and save manpower, he purchased a set of fully automatic CZ purlin interchange equipment in our factory. In steel structures, purlins usually refer to roof frame members that support roof slabs or sheets, or as wall support members. Pre-punched purlins can be quickly installed, suitable for insulated and non-insulated roofs and walls. Housing span and load.

We can provide C Z purlin roll forming machine with convenient operation and full automatic type change. To meet the requirements of customers for automatic type change, we can produce a complete set of CZ purlins with common specifications.

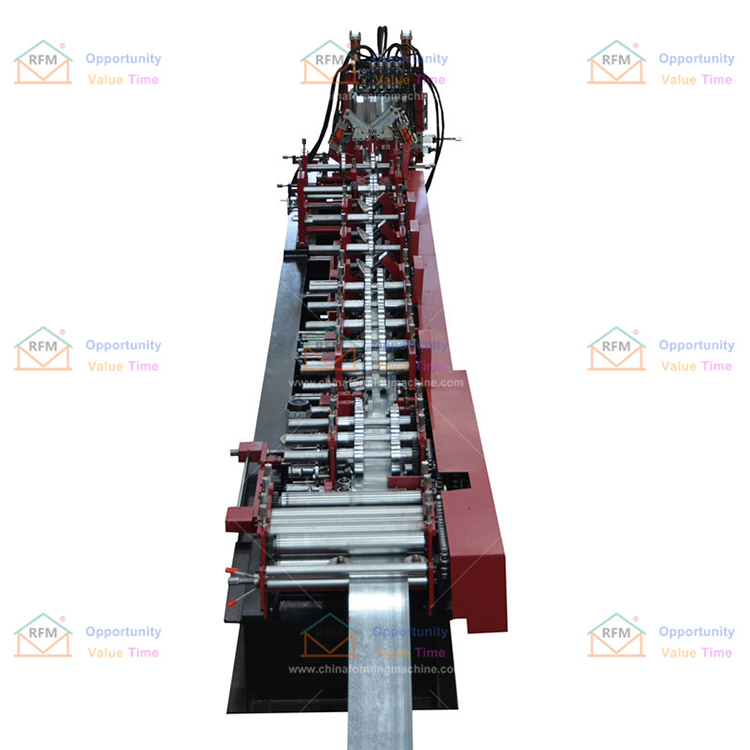

fully automatic CZ purlin forming machine can produce a full set of all specifications of C and Z galvanized steel purlins, and the conversion of C specifications is fully automatic so that the operation is convenient and fast. The lasted machine solve the old model machine problems,such as poor structural strength, poor speed and deviation. The control system is composed of industrial PLC and auxiliary electrical components. The man-machine interactive interface is easy to operate and has high production efficiency. It only takes a few minutes to complete the specification adjustment. Just enter the parameters on the screen and the control system will be automatically adjusted. fully automatic C Z purlin roll forming machine can Shorten operation time, save labor and sample costs.

After Mr. Kate used our fully automatic high-speed inter size C Z purlin roll forming machine . his workers changed the model every time they operated the machine, saving 5 hours of time. Each time you can save dozens of dollars of raw materials.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

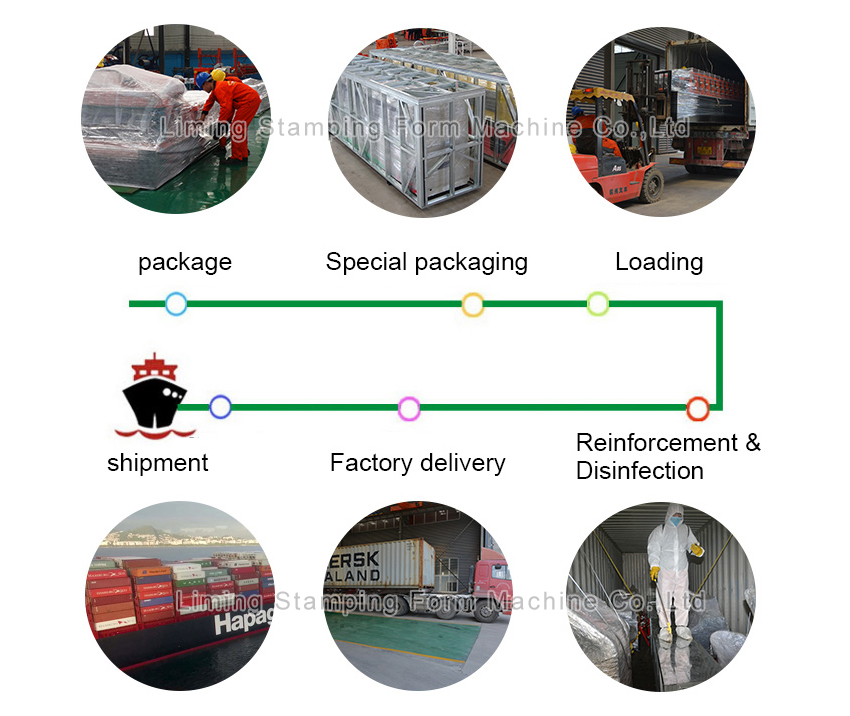

—Product packaging & transportation—