- PRODUCT DETAIL

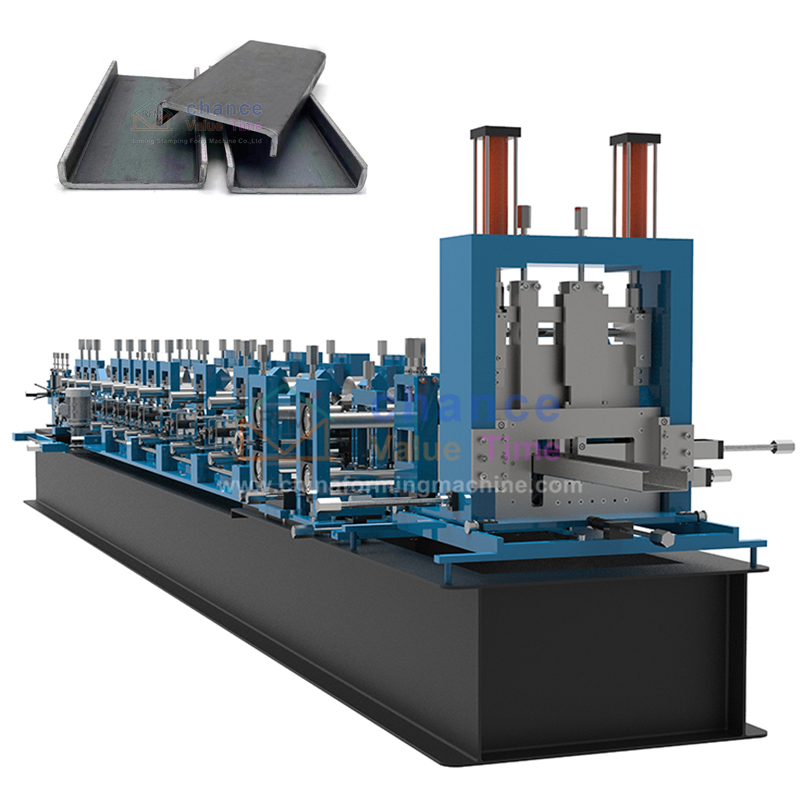

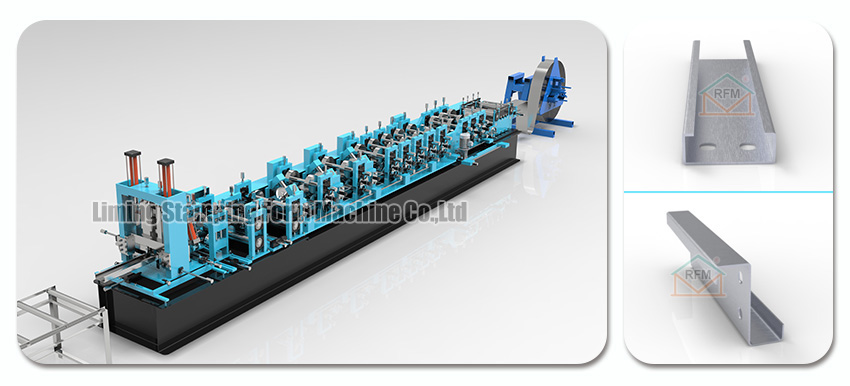

High-Precision CZ Purlin Roll Forming Machine for Durable and Versatile Construction Solutions

Advanced Features:

* Prevent material scratch

* Easy to adjust the material width

* PLC Touch Screen Control allows easy condition setting

The cz purlin roll forming machine adopts German professional design software – Copra design, which realizes seamless docking of European technical standards. We have an industry-leading R&D center, and regularly carry out technical training to update production technology in real time.

The cz purlin roll forming machine is equipped with a well-known high-speed motor, which can continuously provide sufficient kinetic energy for the equipment. In addition, our advanced hydraulic cooling system can control the equipment in a stable temperature range, so our equipment can guarantee 16-hour uninterrupted high-speed production.

In order to ensure that the equipment can be used for a long time, our design team has also designed a new protection device for the equipment, which can be customized according to customer needs. We have CNC-processed protective baffles and 360° full-enclosed protective scaffolds, which can achieve powerful protection functions such as dust and water resistance.

We have more than ten years of professional quality inspection talents and strict quality inspection procedures to ensure that every part of the equipment is of the best quality.

The entire equipment is professional equipment that meets your expectations or even exceeds expectations. In order to provide our customers with better services more intimately, we will also provide customers with more than 2 years of after-sales service, and can also provide customers with on-site installation and free training services.

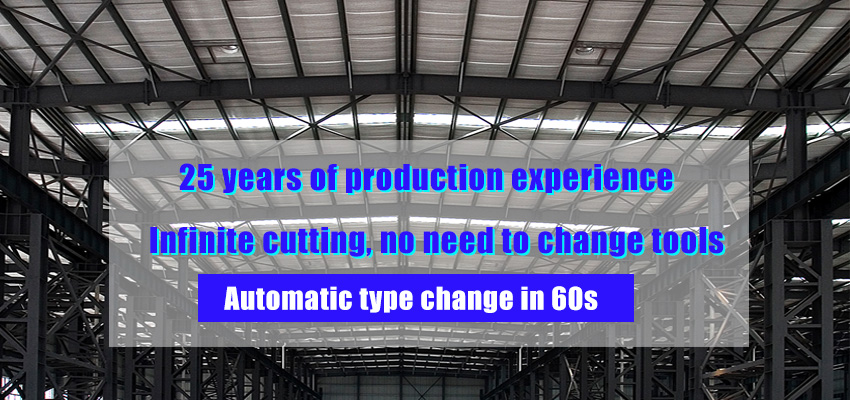

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

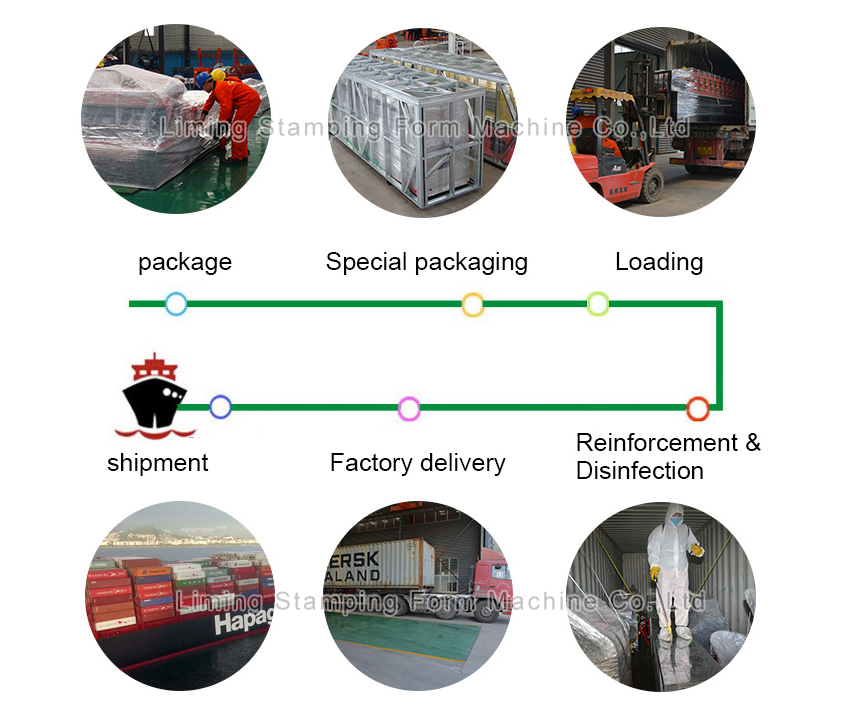

—Product packaging & transportation—

Liming Stamping Form Machine Co., Ltd. was established in 1995. After 27 years of unremitting efforts, it has been developed from the state-owned old factory with 8 employees to the current group with 360 employees and the overall solution provider for industrial chain customers with various roll forming machines.

The combination of world-class AI intelligent control technology and 5G technology provides the customers with remote upgrade services for the machinery. Under the mechanical function, the speed module and LOGO stamping module are upgraded remotely, we continue to optimize the products for you and help you win in market competition. Give us one chance to add the value for your machinery and create more value for you.

Such a goodcz purlin roll forming machine must be delivered to you perfectly, which is the most important result of our QC team that strictly controlling every detail. For the high-quality machinery, in the strict production process, our QC will classify the backup files for each of DV and images of the mechanical package and reinforced package, and send to customers & partners and production managers by E-mail, and hand over the “Mechanical Archive Manual” to the customer with the container.