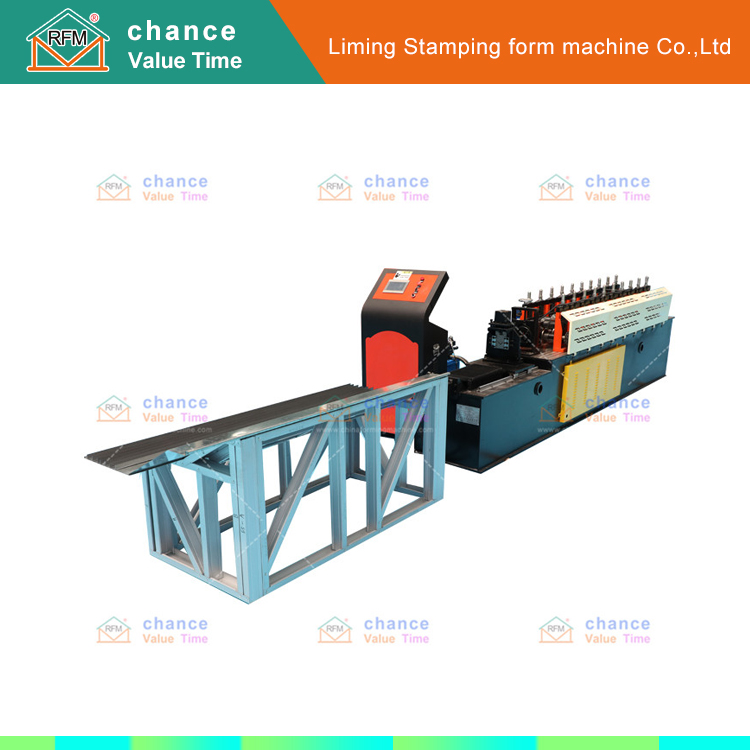

Galvanized drywall partition roll forming machine Specifications

Material

Effective width:About 25 mm

Material Thickness:0.3-0.6mm

Applicable material:Galvanized Steel(GI),Hot Roll Steel(HRC),With yield strength G235-390Mpa

Work Follow

Decoiler→Feeding Guide Device→Rolling Forming System→Hydraulic Not Stop Cutting And Punching Device→ Exit Rack

Machine Components

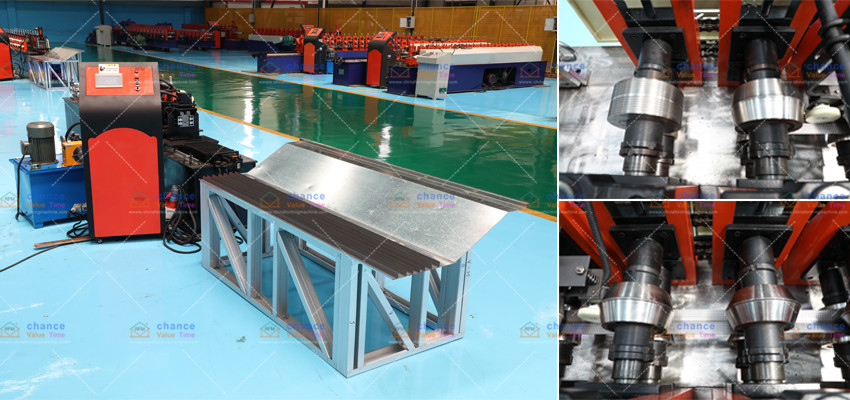

Manual Decoiler 1 Set

Un-powered, Manually control steel coil inner bore shrinkage and stop

Max Feeding width: 500mm,coil ID range ф460-520mm

Capacity:Max 2 Tons*2

We installed an iron plate on the decoiler. What is the role of the iron plate used to fix the steel belt?This baffle must be installed. If the baffle is not installed, the raw material will be stripped and loose during the high-speed operation of the machine, and even the injury may occur.

Secondly, it is a feeding platform. When feeding, we must adjust the height of the raw materials to the position that forms a straight line with the first row of forming molds.

Why do we have two handwheels on one side in the feed material we designed? This one is an upgraded version. It mainly has a more fine-tuning function than that one. It guarantee raw materials before entering the first row of molds. It is already in line with the first row of molds. In this way, the molding is more stable, and the raw materials are less suitable for deviation.

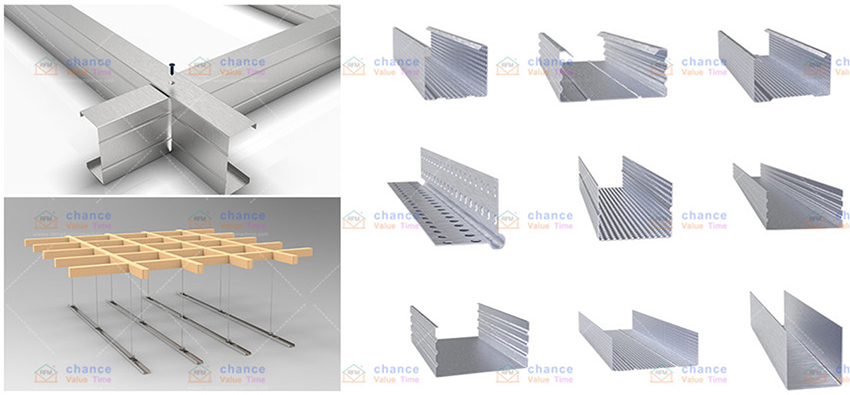

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

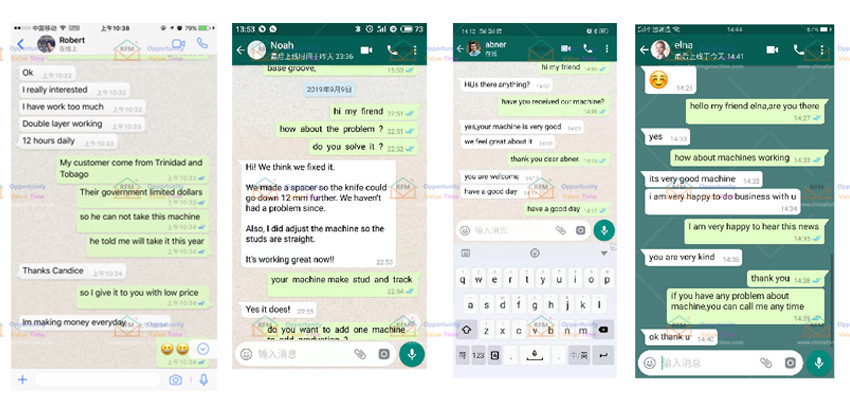

Customer Feedback