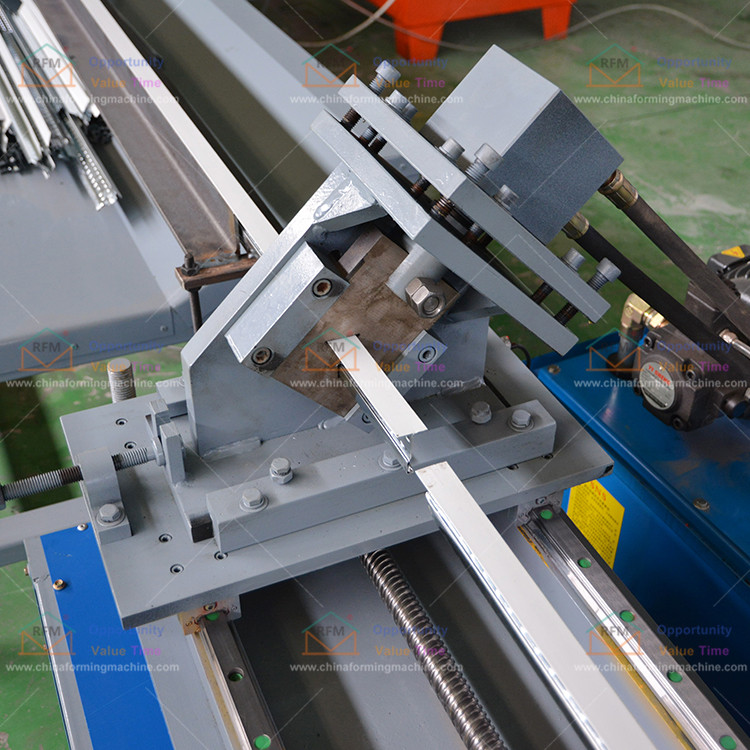

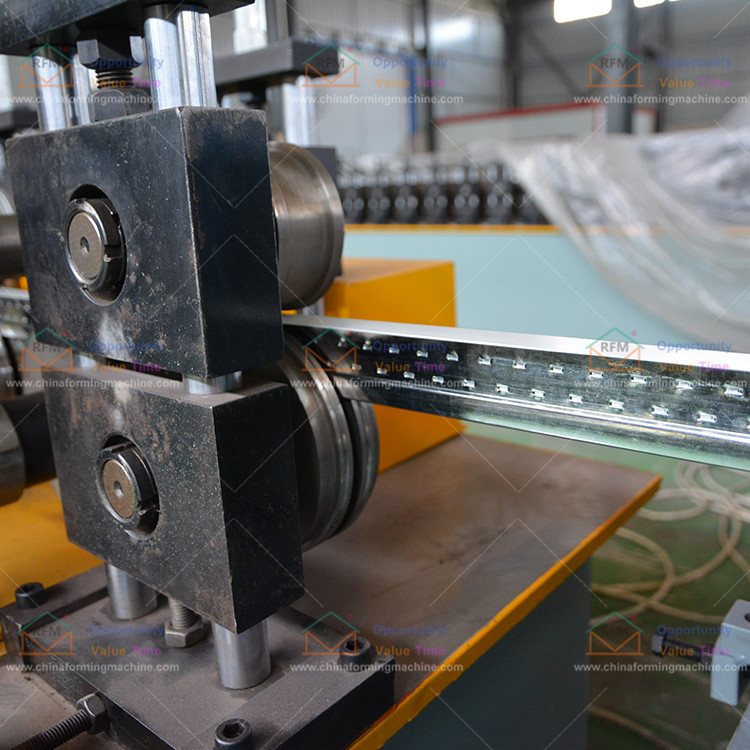

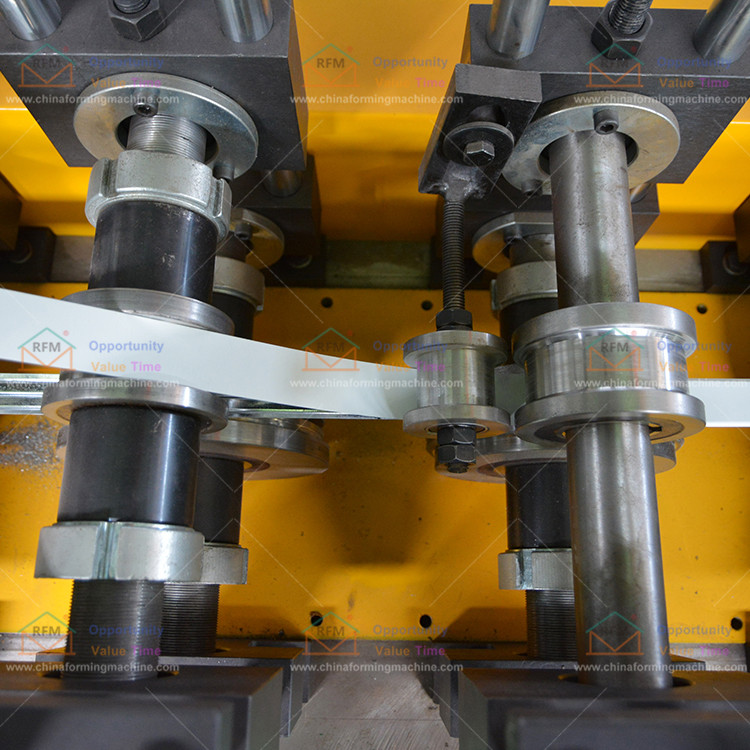

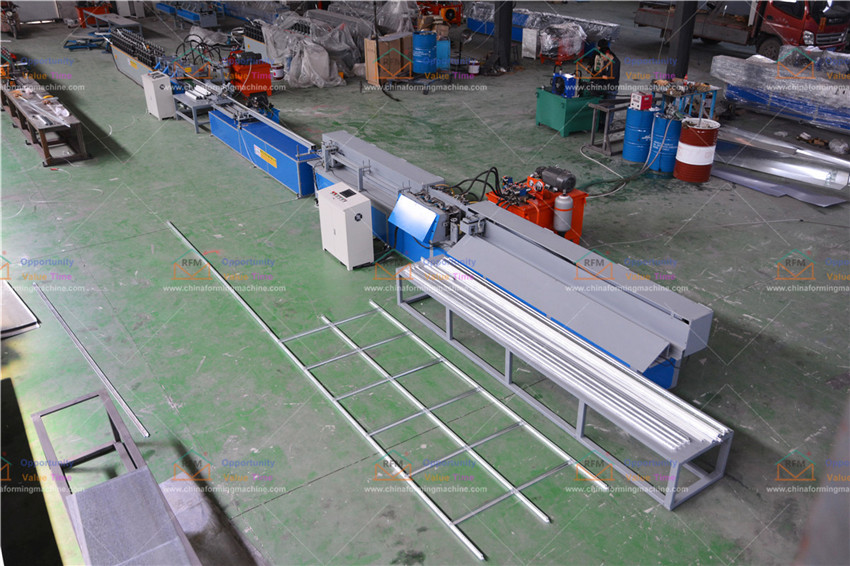

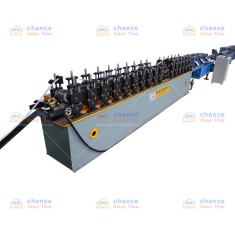

Full automatic T bar keel roll forming machines has two parts, one part is main T bar roll forming machine, and another part is cross T bar roll forming machine, two parts need to be interworking. For each forming line, it include two sets 3 ton electric decoilers, main roll forming machine with punch and cutting, and 3 meters product runout table. 3 ton electric decoiler is automatic working, speed is 15-20m/min, it can match with the punch machine, so can working same time. It can hole coil for inner diameter is 250mm, outer diameter is 450mm, easy operate. Roll forming machine automatic working and controled by Delta PLC control system, we also have Mitsibishi PLC for option. Touch screen easy operate, and we also provide Chinese, English, Spanish, Russia, France, Arab, Japan, Korea languages as customer’s requirement. Both mainT bar and cross T bar was composited formed by two different size of strips. The main T bar international standard length is 1.2 meters or 3.6 meters, and the cross T bar standard length is 0.6 meter and 1.2 meters, so the machine is automatic cut and punch together same time as the standard length. The machine speed can be 20-25m/min. The punch and cutting device is working same time, and controled by PLC.

All the roller and cutter we use Cr12 steel with quenched treatment to make sure the the roller more stronger and not scratch the surface of produce, and the cutter more harder and long lived.

Hydraulic cutter will reduce noise of the machine and it is automatic cut to length as customer’s requirement.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

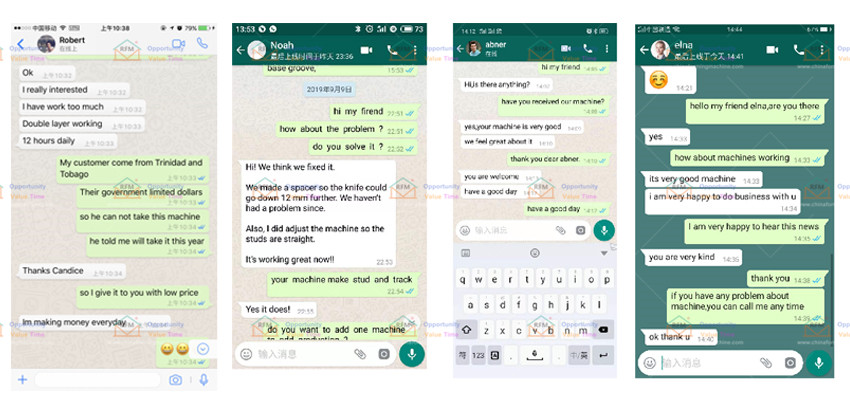

Customer Feedback