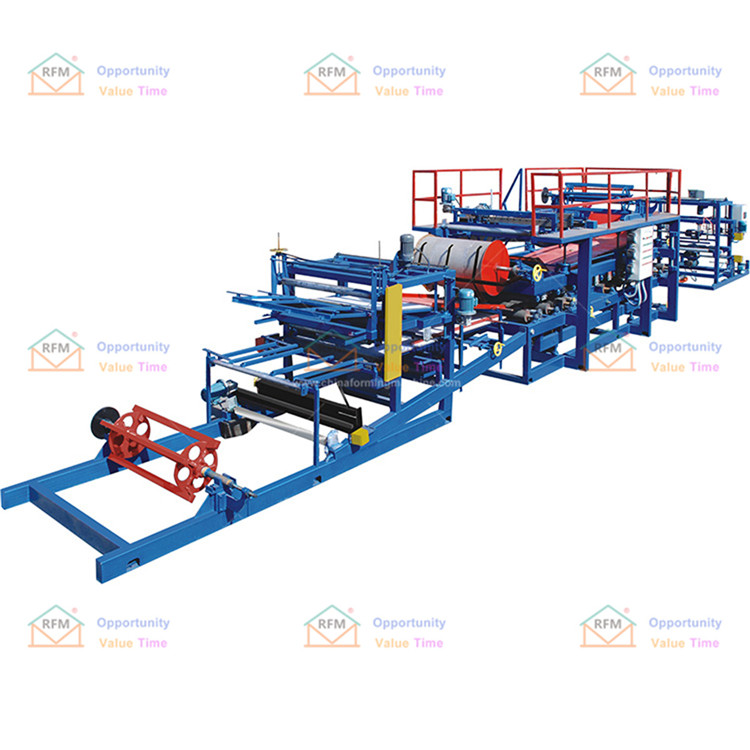

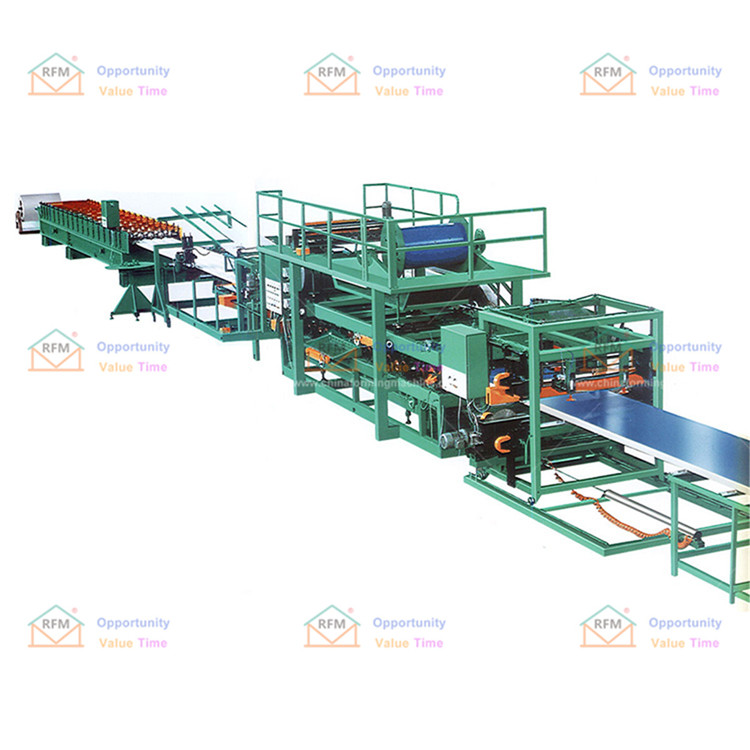

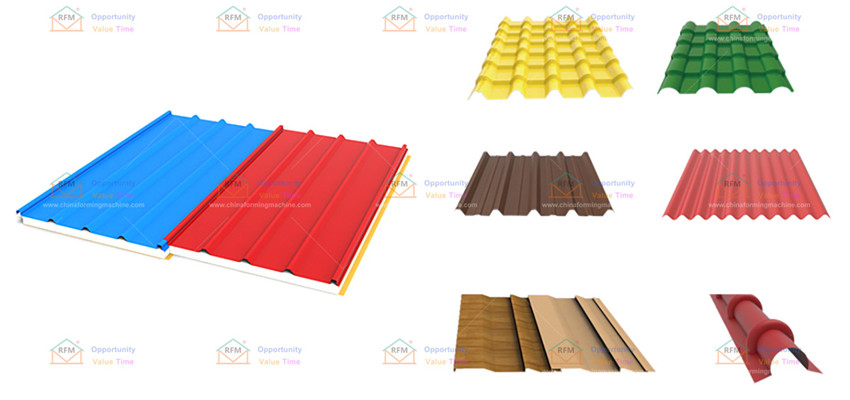

Foam rock wool dual-purpose composite board integrated machine is the main equipment for producing color steel sandwich panel. Color steel sandwich panel is a new type of building material with high strength, light weight, firmness and beautiful appearance.

The foam rock wool dual-purpose composite board integrated machine is easy to construct and has a short construction period, and is widely used in industrial plants. Foam rock wool dual-purpose composite board integrated machine has good thermal insulation performance: inorganic FRP thermal insulation board room.

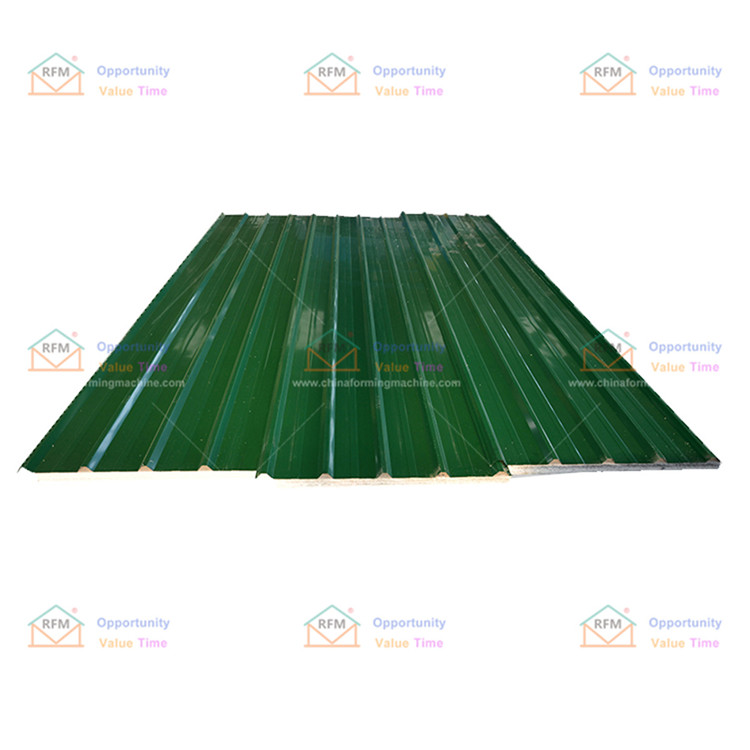

The outer surface is reinforced with glass fiber reinforced plastic material, and the middle is filled with polystyrene foam board, which has good thermal insulation performance, warm in winter and cool in summer, and saves one third of coal used in winter.

Foam rock wool dual-purpose composite board integrated machine has good thermal insulation performance: inorganic glass fiber reinforced plastic insulation board room uses glass fiber reinforced plastic material to increase strength, sandwiched with polystyrene foam board for filling, good thermal insulation performance, warm in winter and cool in summer, saving three points of coal in winter one.

Energy saving and environmental protection: no high temperature and high pressure are needed in the production process; products:, harmless, and non-radioactive, which are green and environmentally friendly new energy-saving building materials.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

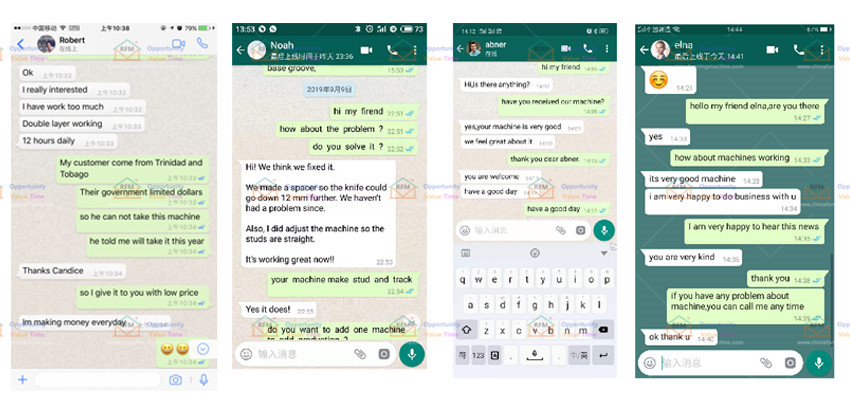

Customer Feedback