I recently met a buyer of a Floor deck roll forming machine, planning to purchase a floor-bearing forming machine,

Our floor-bearing forming machine forming process

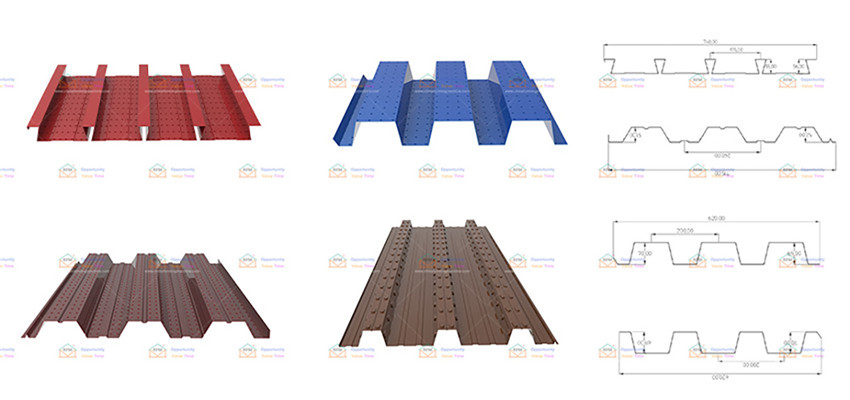

The feed-in platform, forming host, forming shearing device, hydraulic station, computer control system and other parts are the entire production line for the production of floor deck profiles.

Floor deck has the advantages of clean and beautiful appearance, light weight, high strength, heavy bearing capacity, and good seismic resistance; simple and quick construction, convenient assembly; easy construction of reinforcement, wiring, and piping; and other advantages. Therefore, it is very popular in the market.

In addition, our Floor deck roll forming machine has been inspected layer by layer, including raw materials, production, assembly, packaging and other aspects. Afterwards, the machine will be tested. If the produced profile is found to have burrs and scratches on the surface during the test run, the machine will be reformed to ensure that the profile is in good condition.

And if you are just a newcomer in the industry, it doesn’t matter, we have our own design team, which can provide customers with suitable versions for selection and find the most suitable profiles.

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects