What is a sandwich panel?

A sandwich panel is a product used to clad the walls and roofs of buildings. Each panel comprises a core of thermoinsulating material, skinned on both sides with sheet metal. Sandwich panels are not structural materials but curtain materials. The structural forces are carried by the steel framework or other carrier frame to which the sandwich panels are attached.

Any type of sandwich panel will do as cladding for walls and roofs. Depending on the project needs, the cladding may include:

EPS-core sandwich panels (the budget option);

Mineral wool core sandwich panels (for structures with improved resistance to fire);

PIR-core sandwich panels (whenever good thermal insulation parameters are essential).

Sandwich panels can be utilised in all structure types. Your imagination is the limit. However, while sandwich panels are generally used in industrial applications, some housing projects also use stud partitions and sandwich panels.

Given the short installation time and large unit coverage,

sandwich panels are most popular in constructing:

Warehouse buildings

Logistic hubs

Sports facilities

Cold stores and freezers

Shopping malls

Manufacturing buildings

Office buildings

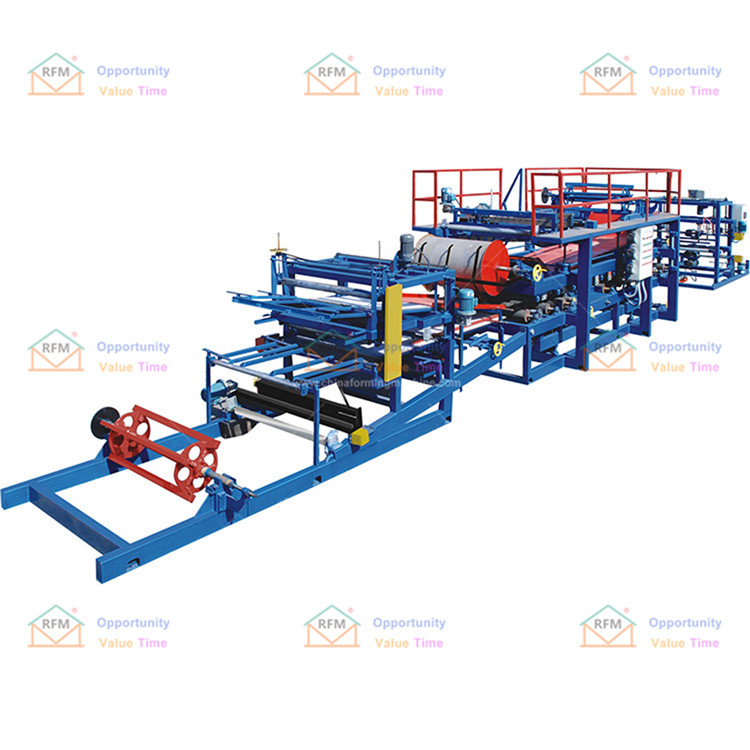

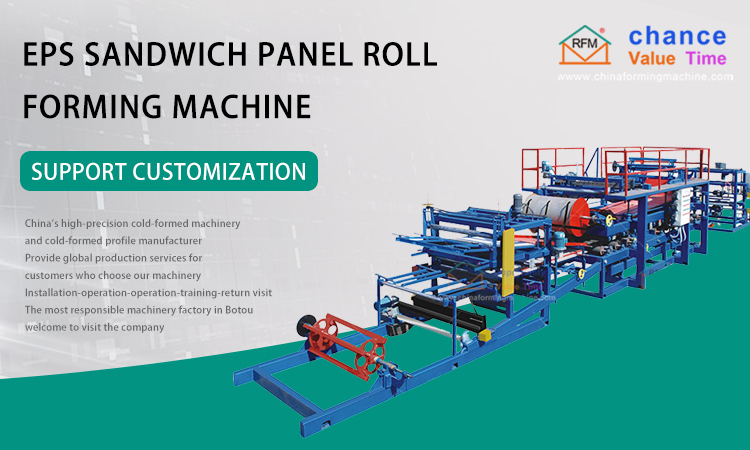

Introduction of EPS sandwich panel roll forming machine:

The EPS sandwich panel roll forming machine is designed for continuous production of metal-finished roof and wall sandwich panels. Because of its simple operation. This EPS sandwich panel roll forming machine is widely used in the construction of steel structure shells, house manufacturers, warehouses, workshops, cold storage and mobile buildings.

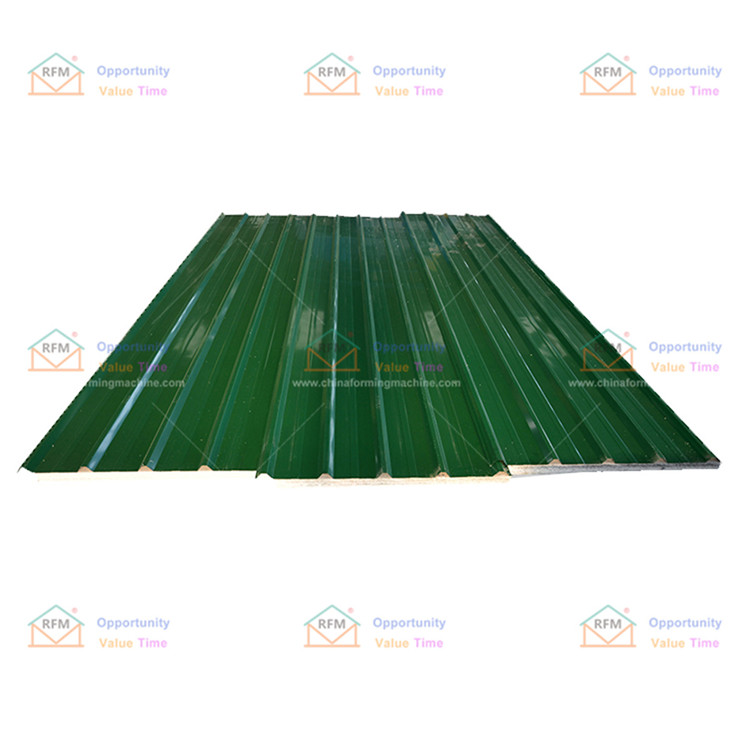

The metal of the roof sandwich panel is a trapezoidal roof panel made of pre-coated steel coils, with a thickness of 0.4-0.7mm and a maximum width of 1250mm (we can design according to the buyer’s requirements);

The thermal conductive material of roof and wall sandwich panels is usually EPS panels.

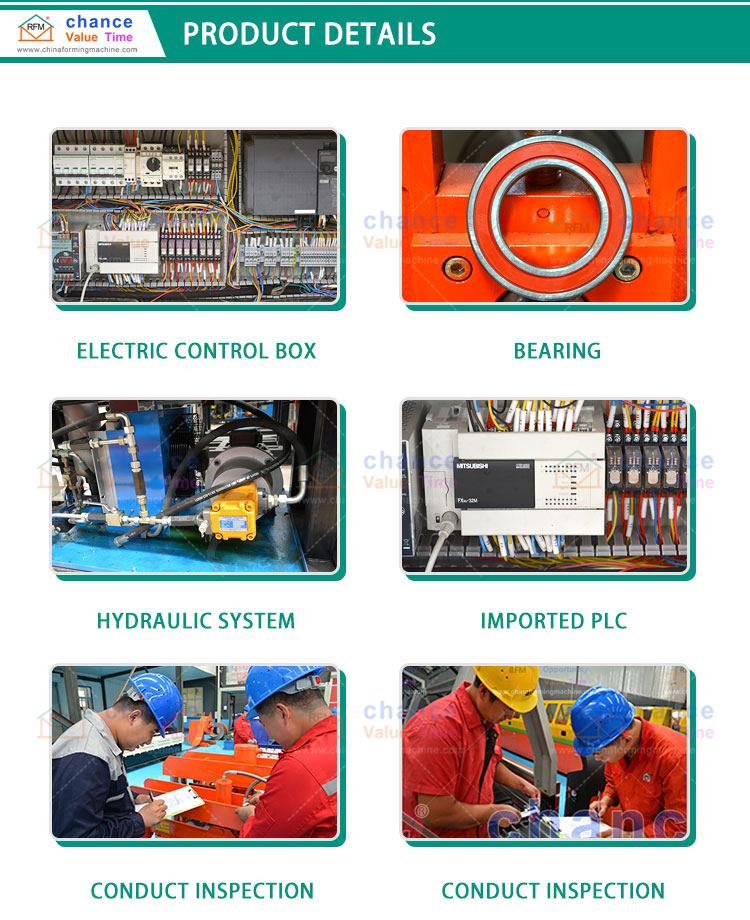

EPS sandwich panel roll forming machine can manufacture polystyrene core sandwich panels. The sandwich panel production line adopts PLC and touch screen control system.

In order to meet various customer requirements, we have designed and manufactured EPS sandwich panel roll forming machine with different specifications, models and configurations.

| EPS SANDWICH PANEL PRODUCTION LINE | ||

| No. | Item | Specification |

| 1 | Face Raw material | Normally 0.2-0.6 aluminum or color steel |

| 2 | Speed | 3-6m/min (Depend on the working temperature) |

| 3 | Cutting type | Trace flying saw cutting |

| 4 | Drive | Chain drive |

| 5 | Electric control system | PLC frequency conversion control |

| 6 | Core material | EPS board or rock wool |

| 7 | Total power | 35kw |

| 8 | Power supply | 380V/50HZ Or Customized |

| 9 | Annual Output | 600 thousand square meters |

| 10 | Product width | 950-1200 mm (Flat Plate) / 950-980 mm (Corrugated Composite Board) |

| 11 | Product thickness | 40-300mm |

| 12 | Equipment overall dimension (mm) |

24000*2100*2600 / 29500*2100*2600 |