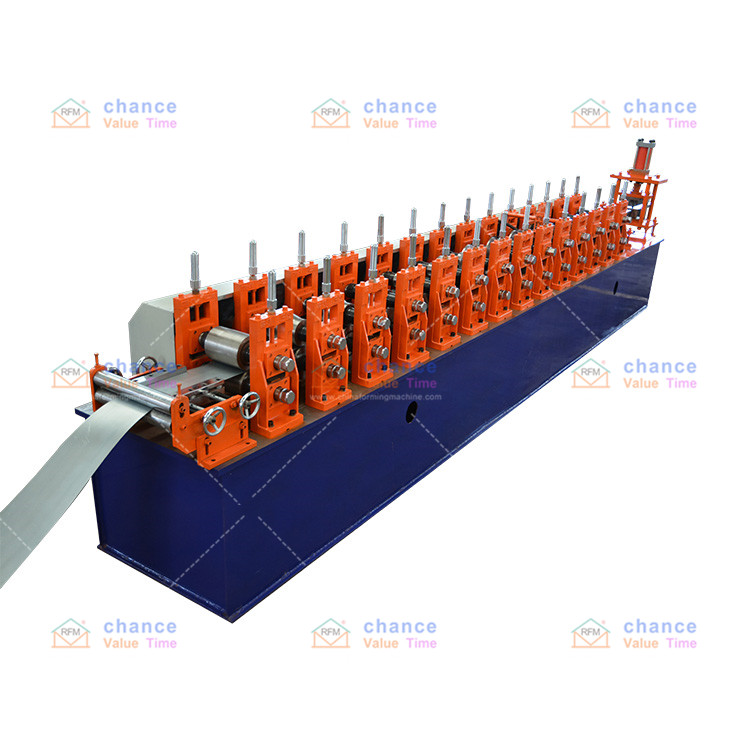

The high-precision elevator guide rail molding equipment produced is a fully automatic molding production line, which saves a lot of labor, and only one person is required to receive the material for a production line.

The special high-speed planer used in the elevator guide rail equipment is developed and designed for the high-precision elevators that require high precision for guide rail processing. It is mainly composed of feeding system, rotating system, dragging system, cutting system and electric control system. The machine tool adopts three-sided wide blade simultaneous planing and drawing technology, with a rotating tool magazine, you can choose several groups of tools for processing according to the use, automatic tool change during processing, clamping using electric permanent magnet worktable, the entire machine tool uses automatic loading and unloading, Automatic positioning and other automatic control, the machine tool is 30 meters long, 12 meters wide, 3 meters high and weighs 130 tons.

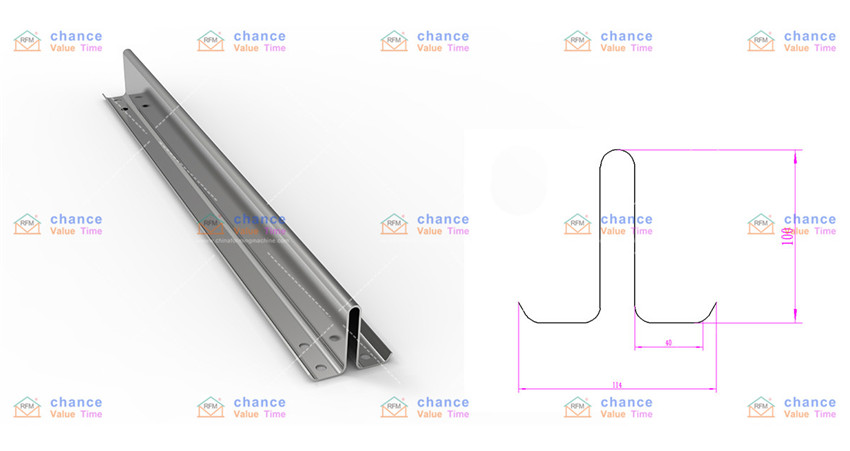

The characteristics of the empty rail of the elevator guide rail equipment. The production line of the elevator guide rail equipment has the characteristics of high accuracy and the production speed reaches more than 4 times of its traditional production line. It can also produce different shapes of guide rail products according to the drawings. The equipment consists of tensioning decoiler-forming machine-correcting machine-disc machine tracking shearing-finished product receiving table, which can produce elevator hollow guide rail and handrail elevator profile.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

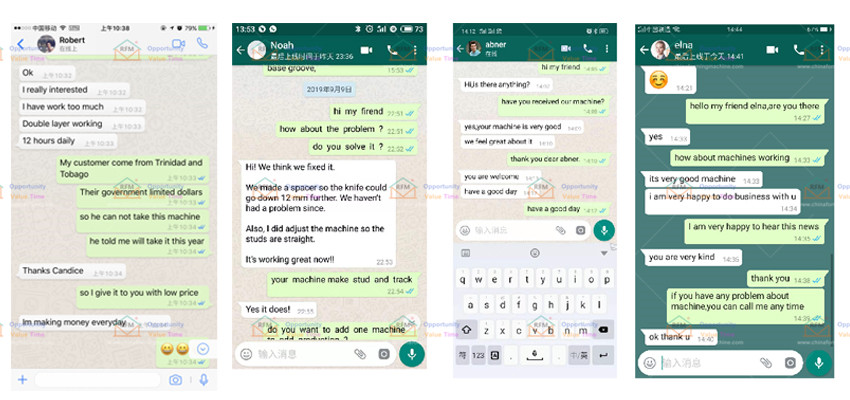

Customer Feedback