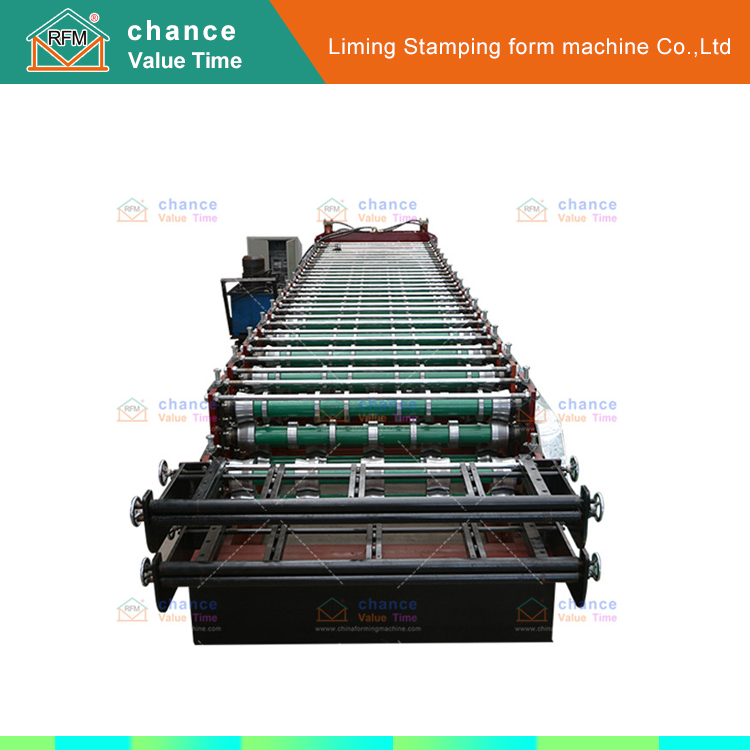

Double-scissors double-layer tile press with double-layer design, one machine for two purposes, small footprint, convenient transportation and cost saving

Some time ago, a customer asked us about the double-scissors double-layer tile press. The upper and lower layers of the double-scissors double-layer tile press are easy to operate. You only need to switch and control each layer separately through the switch button on the electric control cabinet. The power can also be controlled by the clutch. The two models are combined with reasonable structure and beautiful appearance. It has the characteristics of saving space and simple operation, and is especially suitable for customers with small sites and on-site construction. The double-scissors and double-layer tile press adopts split scissors, which are reinforced compared to the middle-fitted double-layer tile press. The pressing plate can be pressed down to 0.8mm. The double-layer laminated tile machine adopts a one-piece middle plate and an inner hanging chain. There are chains on both sides of the machine, and general manufacturers use external single-sided chains. Single-sided chain is not, single-sided transmission, it is easy to run off the board. The inner-hung chain is driven by both sides of the chain to extend the service life of the reducer. The outboard joint is easy to run off and is beautiful.

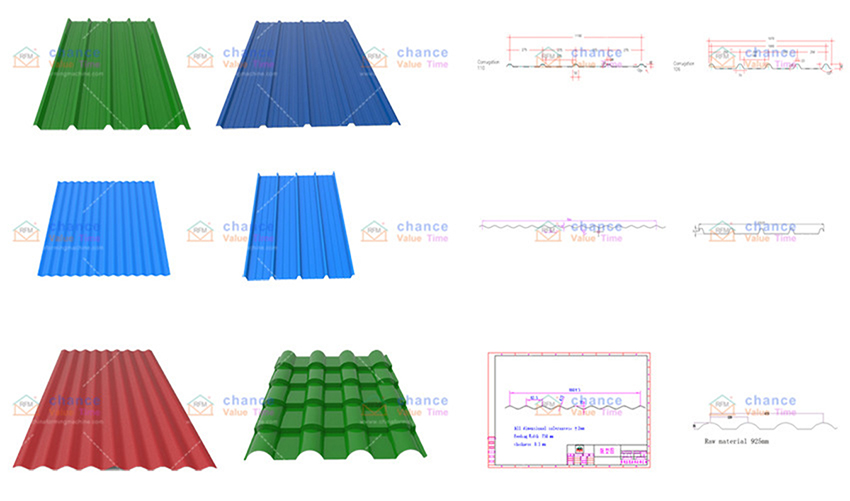

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

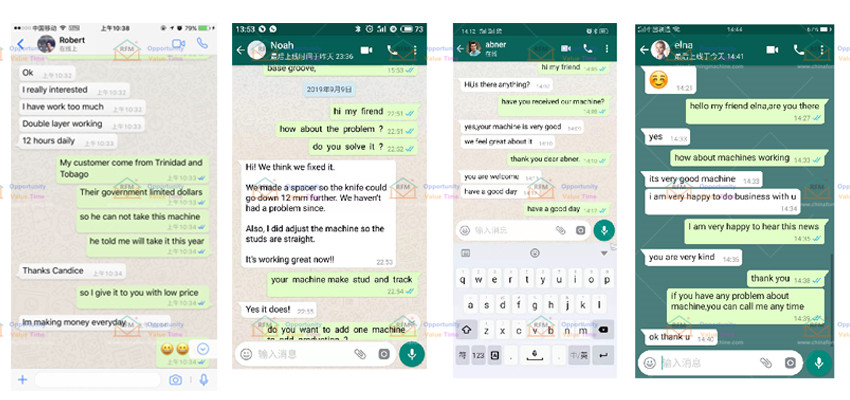

Customer Feedback