Hot-selling space-saving double layer roof panel roll forming machine

Introduction and instructions for double layer roof panel roll forming machine

The roll forming machine has the characteristics of fast forming speed, high output, good performance, less labor, space saving and cost saving. Both are the best choice for the production of sheet metal cold-rolled products.

The forming wheel is the key to the roll forming machine. The rollers used in our roll forming machine are designed by the German software copra to ensure optimal forming. After the rollers are processed by CNC lathes, the forming rollers will be subjected to high-frequency heat treatment to finish the profile again. These processes make the forming roller more precise, avoid deformation during the heat treatment process, and ensure the accuracy and wear resistance of the roller. So as to guarantee the life of the roll forming machine

The price of thedouble layer roof panel roll forming machine depends on the version and budget required by the customer. You can find a second-hand roof panel forming machine anywhere, but if you really want to use the roof tile forming machine for a long time without any trouble or maintenance. You can send your version outline drawing and let our experienced engineers design the metal roof manufacturing machine for you.

Based on our roofs and wall panels at home and abroad, Liming Stamping Form Machine Co.,Ltd has established a manufacturer of roof machines and installed a variety of roof panels with different profiles in its own workshop. Therefore, any customer who needs galvanized and color-coated roofs and wall panels can contact LIMING roll forming machine.

The double layer roof panel roll forming machine has many advantages, including:

Saved floor space

long life

Cost-effective

Higher quality materials

| No. | Item | Specification |

| 1 | PPGI,GI,AI | Width(1000/1200mm) |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.14-0.8mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500*1400*1300(customize) |

| 8 | Speed | 15-35m/min |

| 9 | Diameter of shaft | 70mm |

| 10 | Weight of the Machine | 4-6T |

| 11 | Material of rollers | C45 steel quenched and chromed |

| 12 | Motor brand | Siemens or Guomao |

| 13 | PLC | Siemens or Delta or Mitsubushi |

| 14 | Total power (kw) | 9.5kw |

| 15 | Power of hydraulic system | 5.5kw |

| 16 | Language | English(Support multiple languages) |

Application Range & Scene

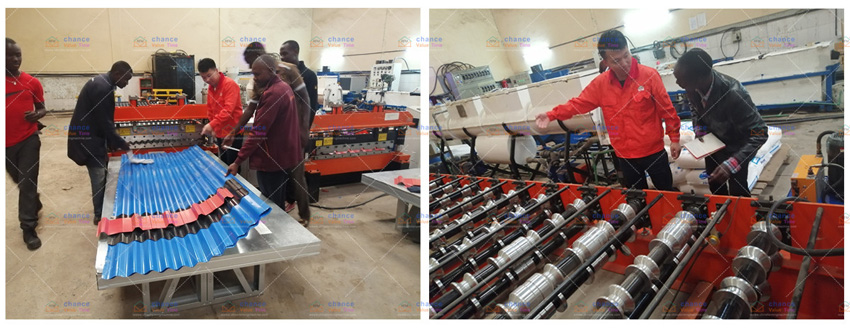

Provide Installation Method & Customized Profile For Free

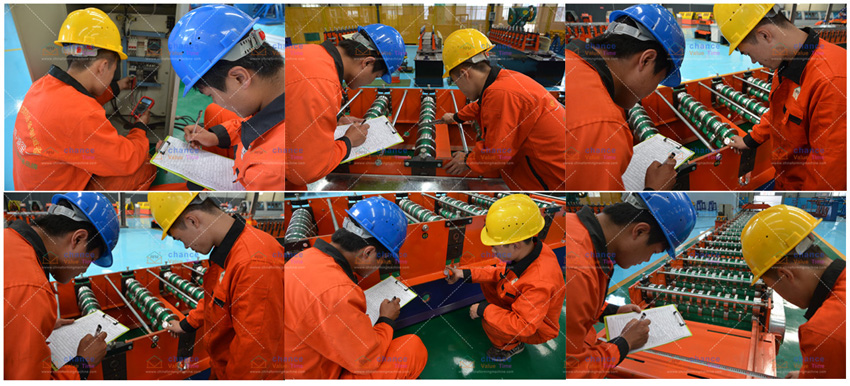

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

The company has perfect after-sales service, can carry out special planning and production according to user needs, and guide users to conduct production, installation, debugging and maintenance together.

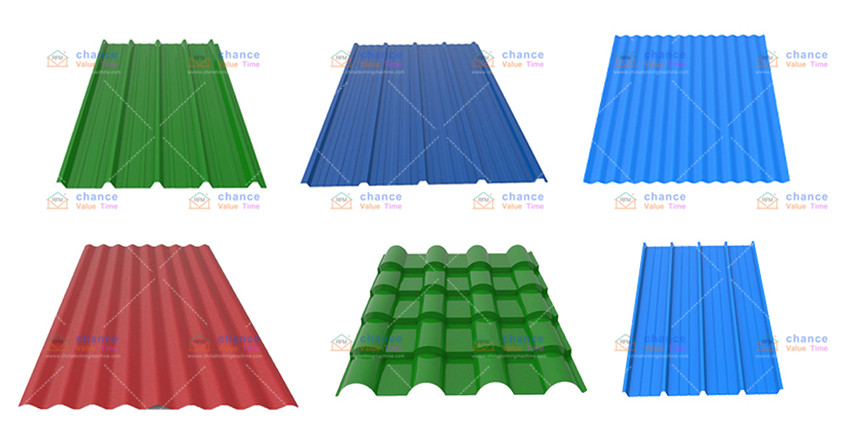

We can produce any type of metal roof panel, wall panel or corrugated board in an automatic roofing panel machine according to customer requirements, such as:

1. Roof panel and corrugated tile forming machine

2. Wallboard corrugating machine

3. Roof panel production line

4. 2 in 1 roll forming machine

5. Steel double-layer roll forming machine

6. double layer roof panel roll forming machine

7. Glazed tile and IBR double-layer roll forming machine