High quality building roof double layer roll forming machine

Click to view detailed production video

Have you ever been confused by not knowing how to choose a machine? Do you want to produce two profile with one machine or two machines? Hope the following story can give you some guidance and help.

Mr. Qutaiba from Sudan is an ambitious young man. After graduation, he did financial management in a company to learn the operation of the entire company and then started his own business. After researching the market, Mr. Qutaiba chose two hot-selling versions of the local market and prepared to purchase machines to produce these two profile.

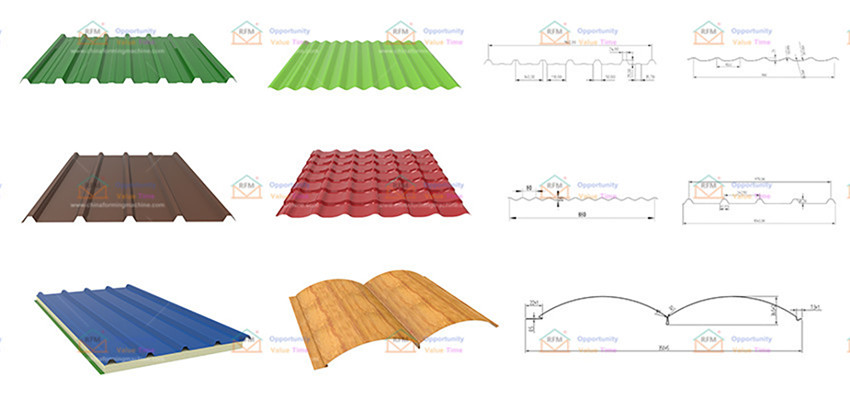

According to his plant area, budget and the status of the business that has just started, we especially recommended the farmhouse used roofing and glazed tiles double layer roll forming machine. In particular, we designed the layout of the double layer roll forming machine placement in the workshop to provide all aspects of services for Mr. Qutaiba who has newly entered the industry. The cutting system of our roofing and glazed tiles double layer roll forming machine adopts the cutting method of two double guide columns. The cutting blade is made of Cr12 material. The precision of cutting and the long service life of the layer forming equipment. Because of precise layout and high-quality finished products, Mr. Qutaiba quickly gained the trust of local customers, and more and more orders. Now the customer has recovered the cost of the machine and earned a high profit. With the increase in production, he has now ordered two separately produced equipment with us.

This is a double layer roll forming machine, it is the most correct choice to meet your needs.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

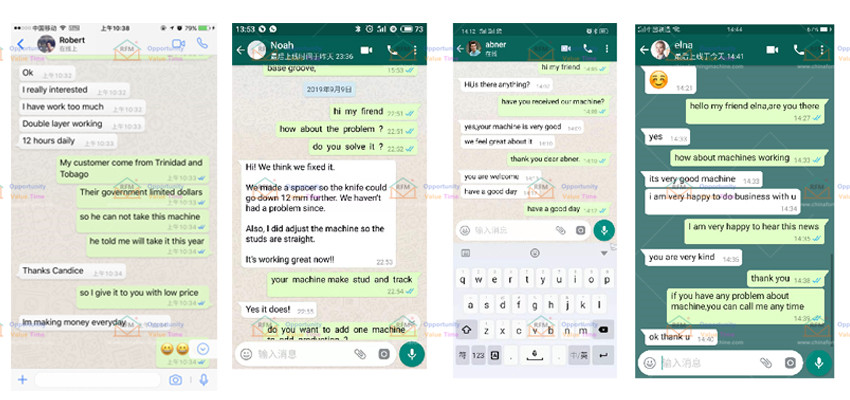

Customer Feedback