Double Keel Roll Forming Machine

Double keel roll forming machine can produce two types tile. TIt is

controlled by gear wheel through oil pump. Before beginning the cutting job,

the hydraulic oil should add into the hydraulic oil tank, so the pumps can drive

the cutter machine to start. The system includes a set of hydraulic tank, a set

of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism

valves.

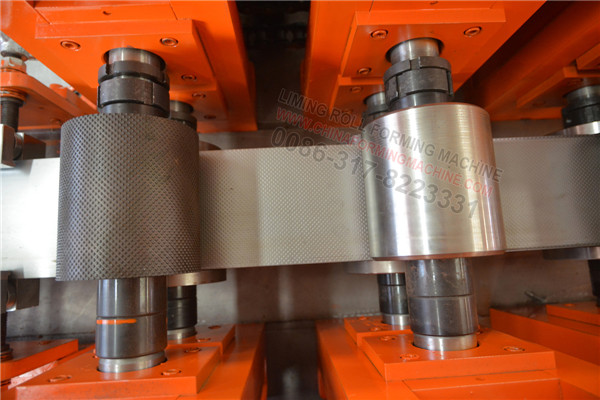

Double keel roll

forming machine is

made of the following parts:

A. Manual uncoiler—————————————–2

sets;

B. Guide platform——————————————-2

sets;

C. Roll forming host—————————————-1

set;

D. Mould cutting device———————————-2

sets;

E. Output rack———————————————–2

sets;

F. Mail

motor————————————————2 sets;

G.

Encoder—————————————————2 sets;

H. Hydraulic

station—————————————1 set;

I . PLC control system————————————-1

set;

J. Electronic

components——————————–1 set.

Double keel roll forming machine adopts

industrial computer to control. The length of target pieces is adjustable and a

digit of it can be adjusted. The system is easy to operate and use. It contains

liquid crystal screen, programmer, transformer for the electronic machines and

kits of every part. The operation of double layer roll forming machine can has

two modes, for one is automatic and the other is manual one. The system is easy

to operate and use. It contains liquid crystal screen, programmer, transformer

for the electronic machines and kits of every part.

Our factory established in 1996, is professional manufacturer.

Our factory is the biggest designing and manufacturing

supplier of roll forming machine in North China.

We have the full professional engineer team, which

have rich experience for many years.

We can customize machine as per detail profile drawing.

Our machines have passed CE certification through the

inspection of BV company. This certification has the highest authority in this

industry