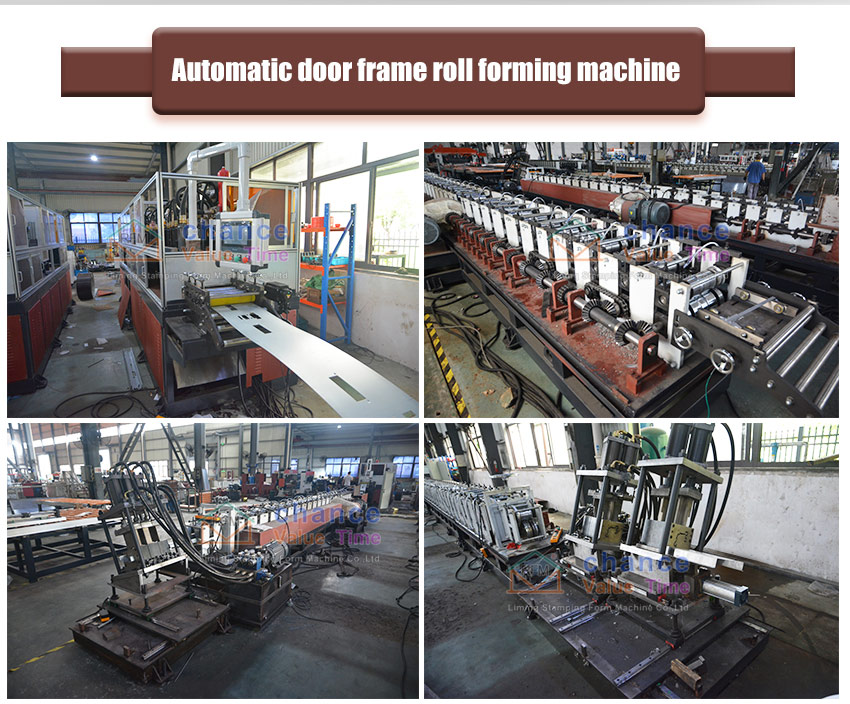

Door frame roll forming machine

Door frame roll forming machine manufacturer — Discounted ex-factory price

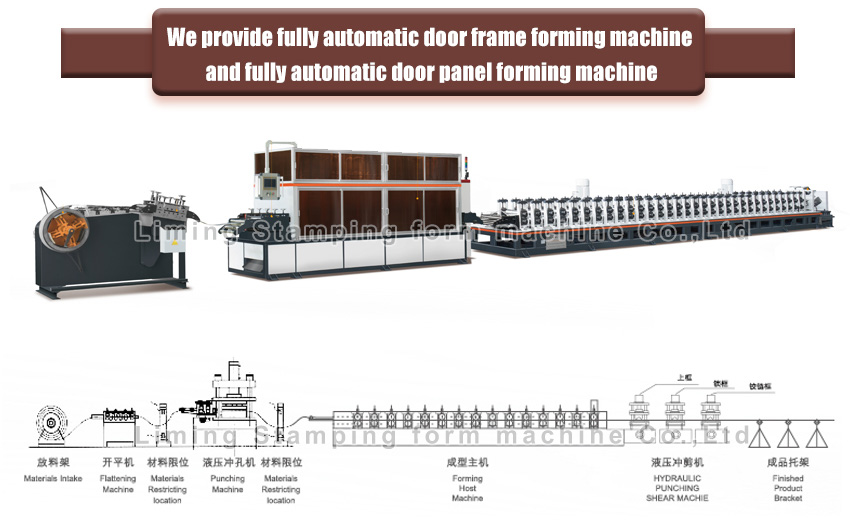

Working process of door frame roll forming machine

The automatic door frame roll forming machine is composed of three parts: a steel plate leveling machine, a profile forming machine, and a 45-degree angle cutting machine. The feed drive motor of the steel plate leveling machine is 3KW, and the feed drive motor of the profile forming machine is 7.5KW. Because the steel plate leveling machine is far away from the other two parts, it is not convenient for centralized control and operation, and because the length of the connection between the encoder and the control system cannot be too long, the control system is divided into two parts, one controls the steel plate leveling machine, and the other A control profile forming machine and 45 degree angle cutting machine.

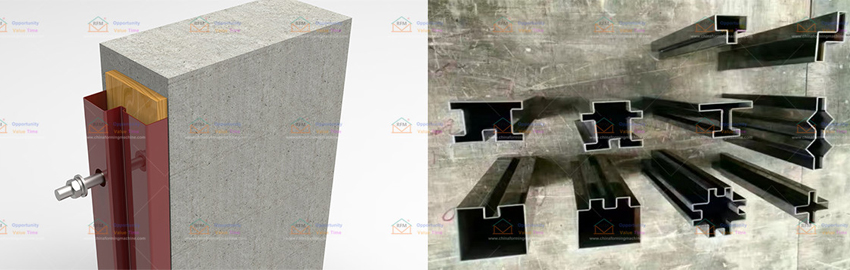

Its working process is like this: the coiled steel plate enters the steel plate leveling machine and will be corrected into a flat plate through multiple pairs of leveling rollers and completed opening the hinge hole or key hole, and then enters the profile forming machine and is formed by multiple pairs of molds step by step. , It becomes a profile that meets the design requirements, and then punches the mounting holes and cuts it according to the set length. The 45-degree angle machine cuts 45-degree welding grooves on both ends of the door frame profile as required.

The main products of LIMING forming machine company are door frame roll forming machine, fire window forming machine, door panel forming machine, door leaf flanging machine, combination punch, hydraulic punch, automatic hot pressing machine, door frame automatic assembly line, door leaf automatic assembly line.