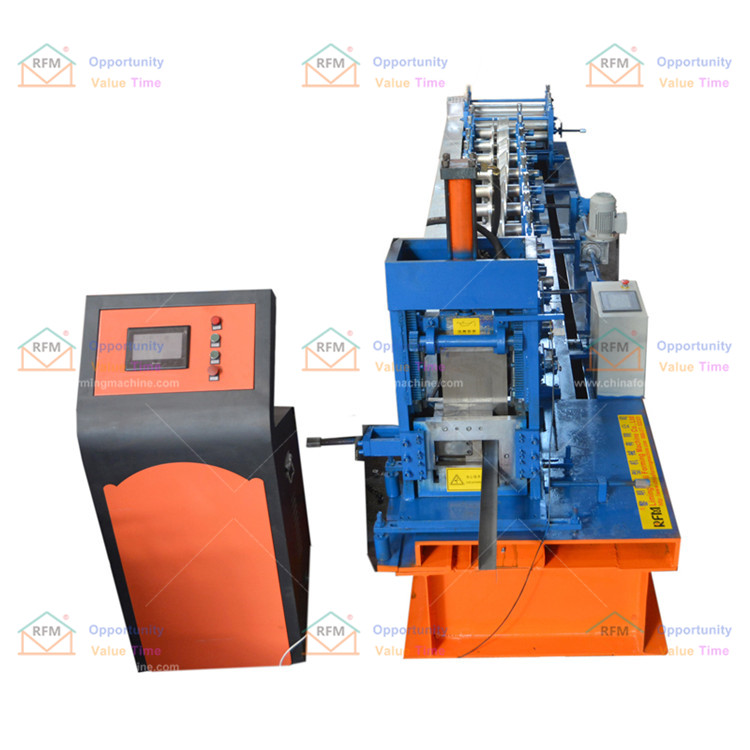

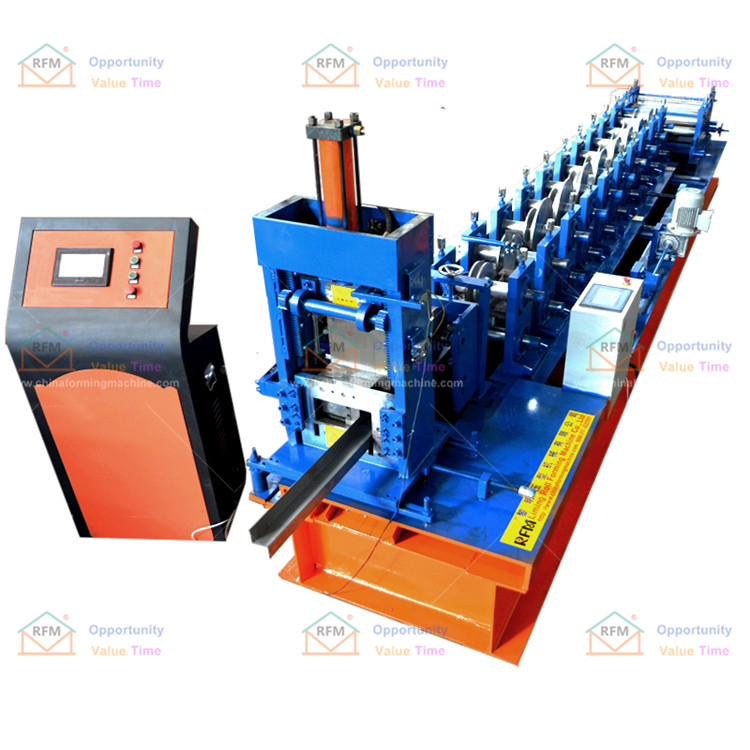

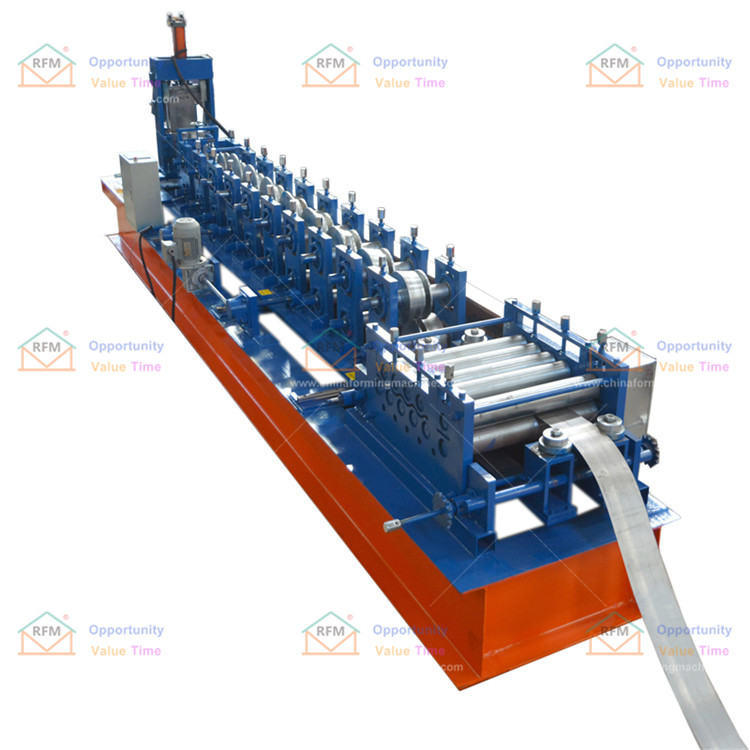

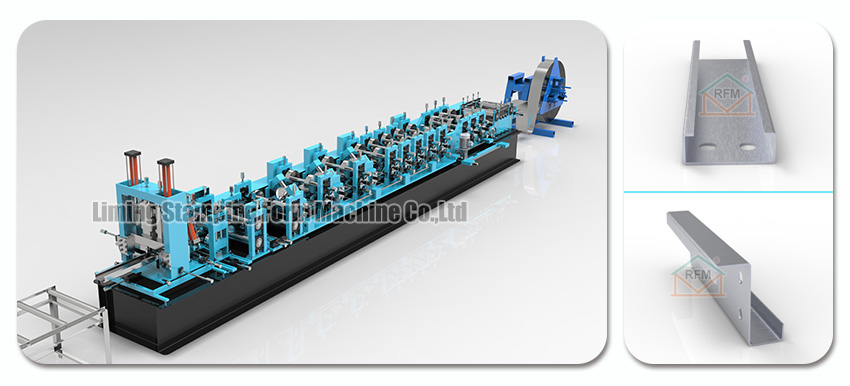

In June, we received an inquiry. This customer mainly produces the roof of the market flower shed. We therefore recommended Z-shaped steel to him. The finished product of Z-shaped purlin rolled by Z-shaped steel mill has good bending and compression resistance, good flatness, automatic fixed-length cutting, automatic punching, high degree of automation, and quick and convenient installation. Z-shaped steel machine products can be used as the main force-bearing structure of large and medium-sized industrial and civil buildings, such as factory buildings, warehouses, hangars, hangars, exhibition halls, theaters, stadiums, and market flower sheds for roof load-bearing and wall supports. The Z-shaped steel machine is mainly composed of a feeding frame, a feeding frame base, a feeding introduction platform, a leveling device, a forming host, a punching device, a forming and cutting device, a hydraulic station, and a computer control cabinet.

The wall thickness of Z-shaped steel equipment can be made very thin, and the production process is greatly simplified, and the production efficiency is improved. It can produce various profiles and cold-formed steels of different materials with uniform wall thickness but complex cross-sectional shapes that are difficult to produce by general hot rolling methods.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

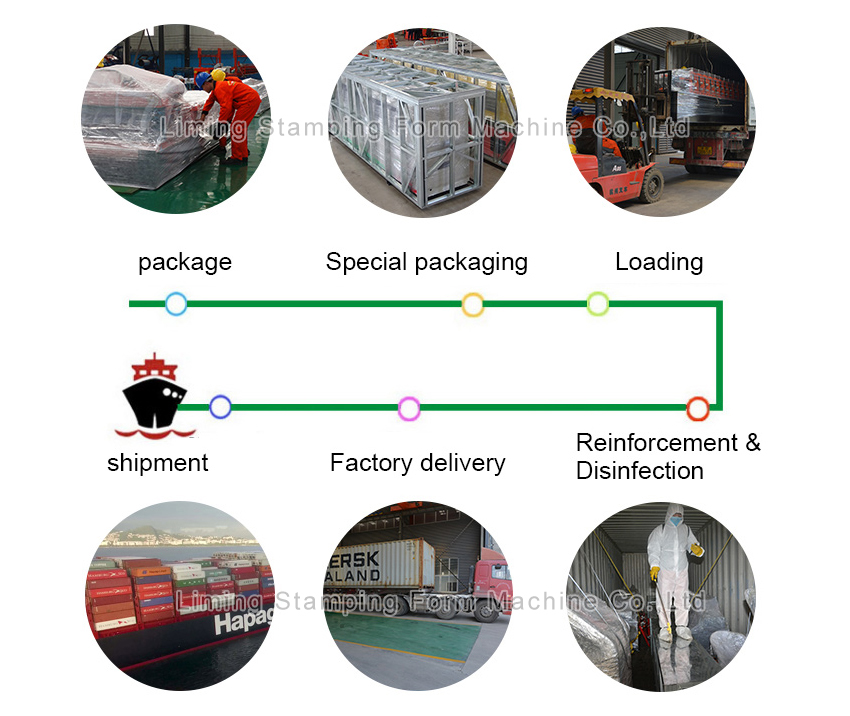

—Product packaging & transportation—