CZ purlin forming machine used in steel structure workshop

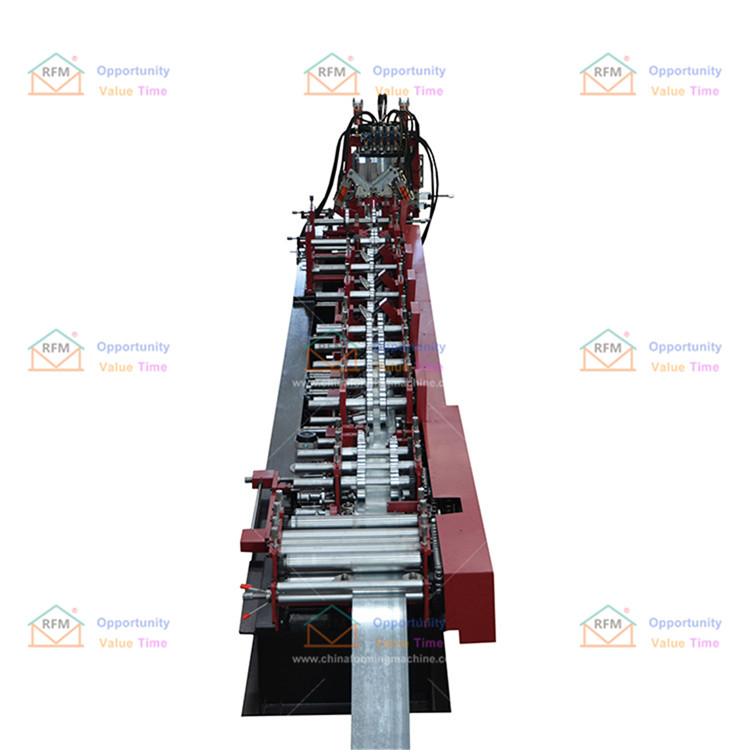

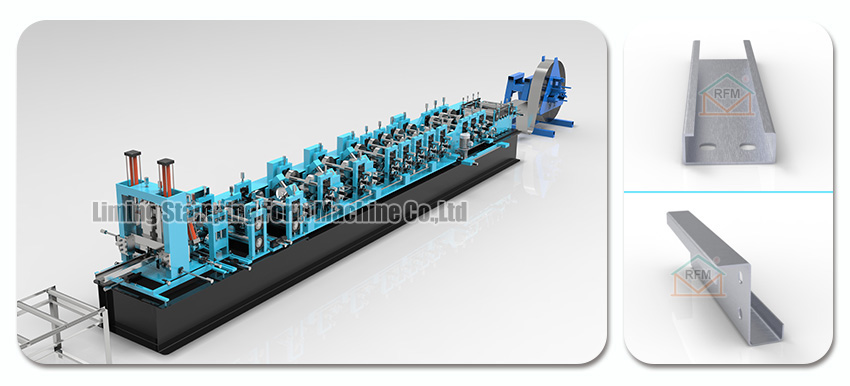

Fully automatic CZ purlin forming machine is mainly composed of passive loading rack, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc.

This CZ purlin forming machine adopts automatic flying saw punching, easy to operate and so on. The main purpose products can be used as the main force-bearing structure of large and medium-sized industrial civil buildings. C-shaped steel machine, also known as C-shaped steel sandal bar machine, is one of many varieties of tile pressing machine, and it is a basic type of tile pressing machine. Unlike the color steel plate forming machine, it is hydraulically powered and has a large power, generally around 22KW. Similar to the shearing and bending machine, the general control process is complicated and PLC control is mostly used.

Technological process of fully automatic CZ purlin forming machine: Strip steel is fed from the rear of the equipment, and pressed into C-shaped steel by various pressing rollers and sent from the head. In the traditional process, the C shaped steel needs to be manually cut to a fixed length after being pressed and then transported to the punching equipment to punch according to the size required by the customer. The production cannot be continuous and the efficiency is not high.

Fully automatic CZ purlin forming machine is a set of rolls that can produce various specifications of C-type purlin finished single-roll forming unit. This machine is mainly composed of passive loading rack, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc. This machine adopts automatic flying saw punching, easy to operate and so on. The main purpose products of CZ purlin forming machine can be used as the main force-bearing structure of large and medium-sized industrial civil buildings.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Product packaging & transportation—