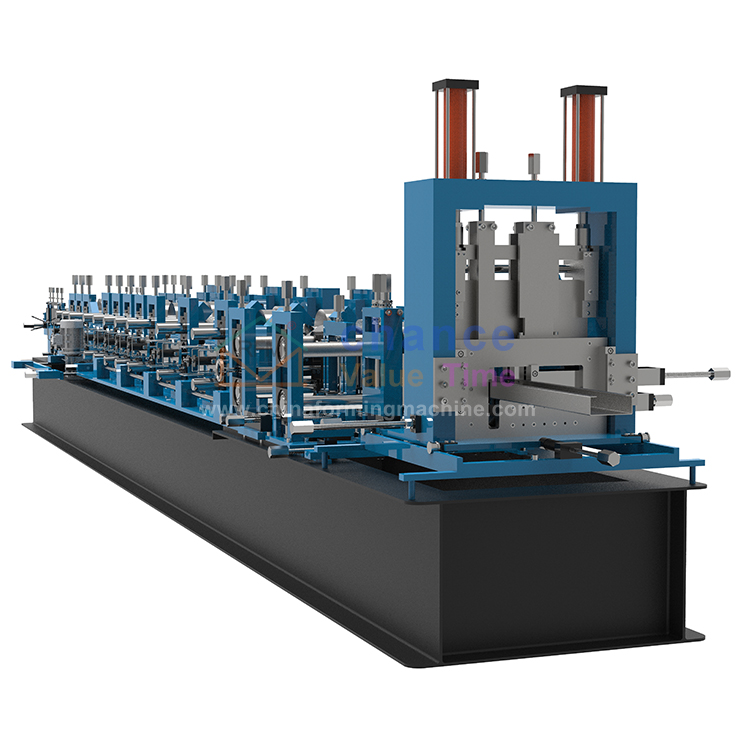

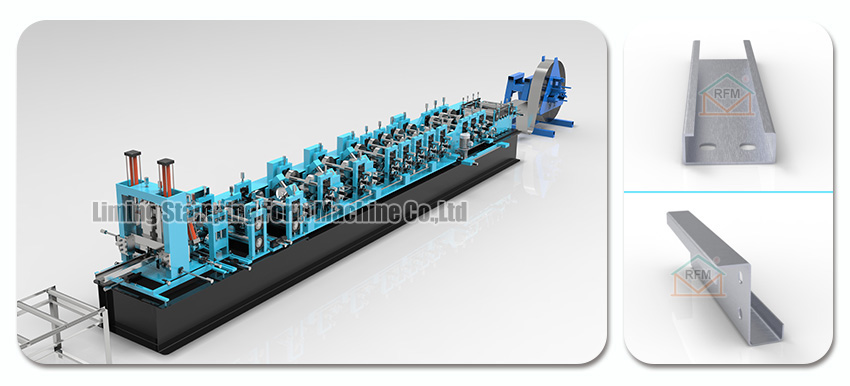

Automatic type change CZ purlin forming machine

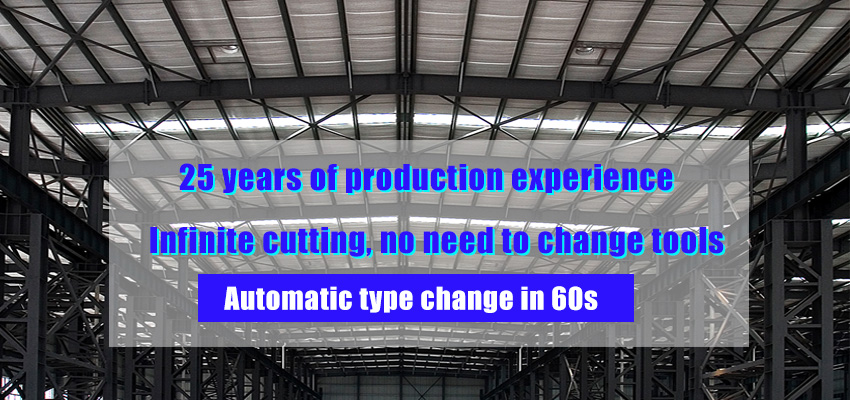

In May, an Egyptian customer wanted to purchase a CZ purlin forming machine. As a steel structure contractor, he urgently needs a machine that can produce C and Z purlins, and the cost of the two machines is much higher, so he chose the CZ purlin forming machine.

CZ purlin forming machine production video

When there is no engineering, he is also selling CZ profiles, and the two products and full-size products are very popular with customers.

The CZ purlin forming machine has undergone many stages of changes in China, from unchangeable to ever-changing.

Later, many different methods (such as cable ties, tension springs and bolt locks, clearance coordination, etc.) were used on the changed half sets, but these methods did not fundamentally solve the essential problems of production, but were in production. A long time was wasted in the process beyond value. These processes consume most of the production cost, so we urgently need to change.

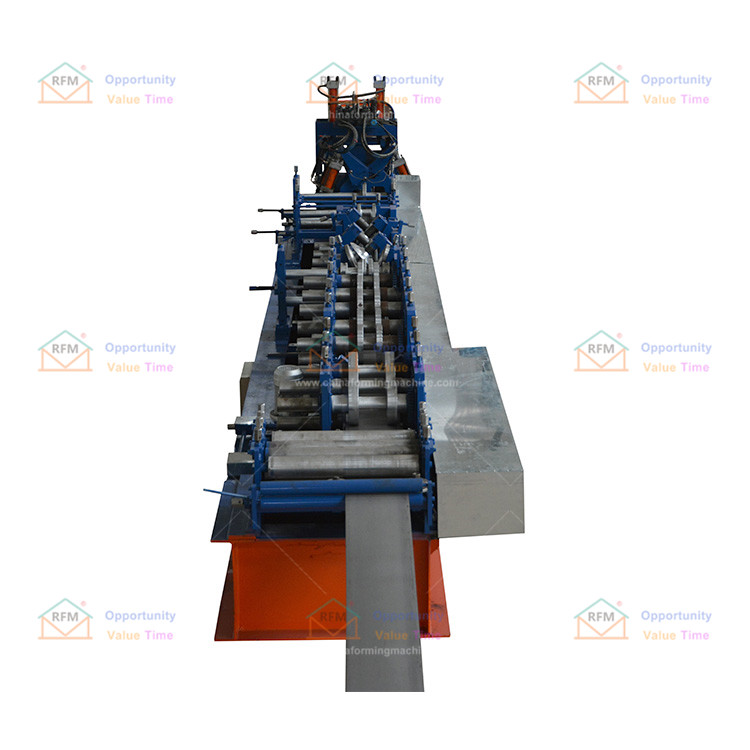

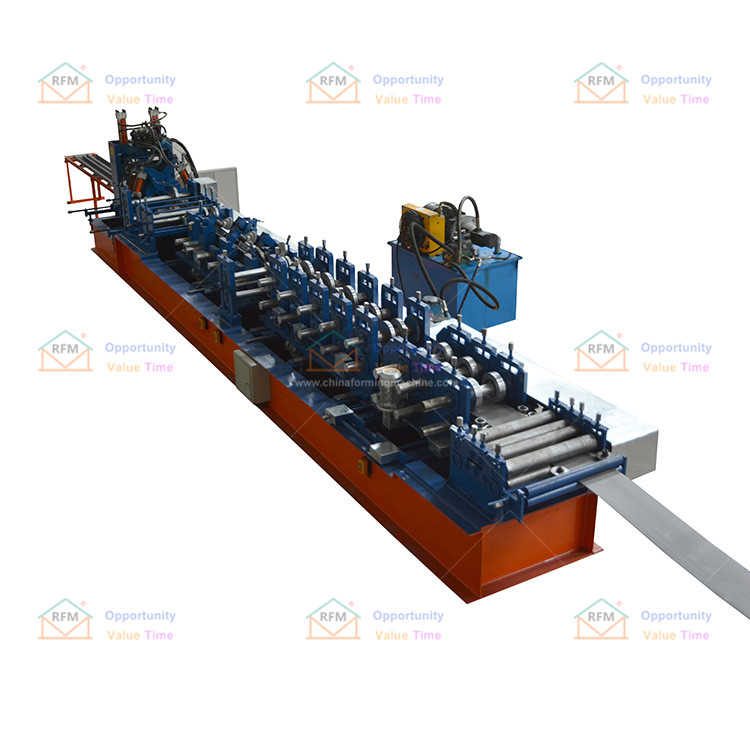

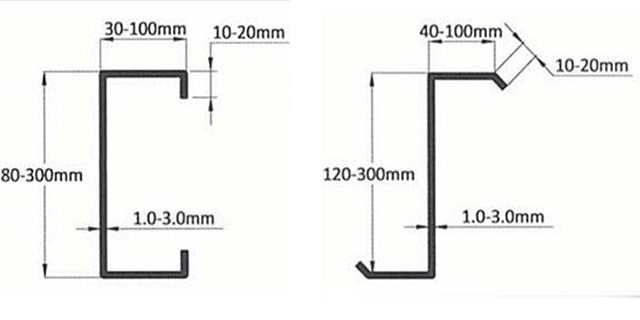

The CZ purlin forming machine can form 1-3mm raw materials, which is used as a support for the steel structure, which greatly improves the load-bearing problem of houses, workshops and workshops; and the CZ purlin forming machine can be adjusted to produce different types of products, and can also be used Connect on the roof.

If you are a profile supermarket, CZ purlin forming machine can also produce different products for you to quickly seize the market.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 1-3mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |