Steel Slitting Machine at Best price in china

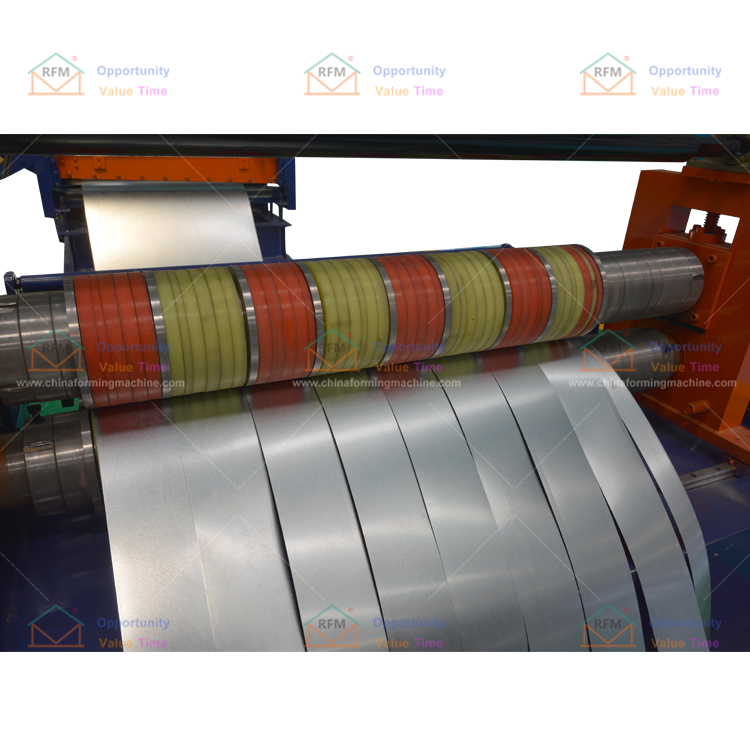

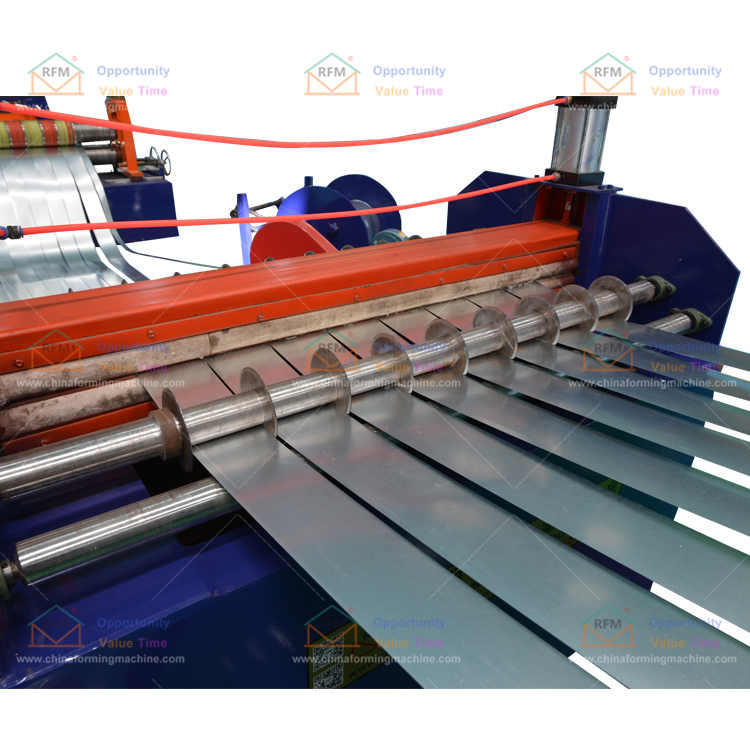

Steel Slitting Machine process:

Thin plate: unwinding saddle—feeding trolley—uncoiler—roller guide—looper—correcting and centering—slitting machine—waste wire machine—live Sets—Separator—Tightening machine—Winding machine—Unloading car

Thick plate: unwinding saddle—feeding trolley—decoiler—rough leveling machine—scissor—looper—correction and centering—slitting machine- –Scrap machine—Transition table—Separator—Fine leveling machine—Shearing machine—Throwing machine—Blanking trolley

Service Commitment of Copper Strip Slitting Machine:

1. On-site training: During the on-site commissioning, technical training on operation and maintenance will be provided to the users of copper strip slitting machine operation and maintenance personnel, so that users can operate proficiently and master the handling methods of common failures.

2. After-sales service provides relevant technical services, provides technical consultation, answers, and technical training to users, provides technical information related to use and operation

3. Technical after-sales service for users (1+1), that is, after a piece of equipment leaves the factory, there will be a full-time engineer to provide perennial technical tracking service

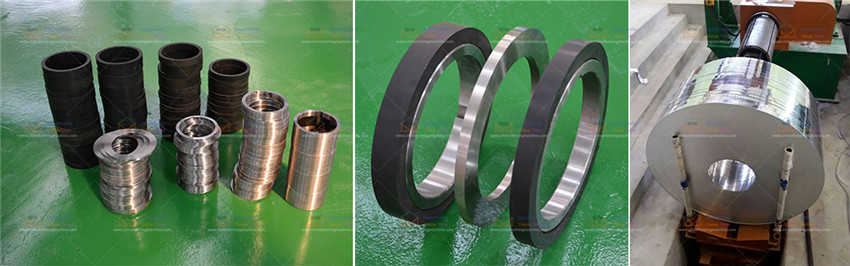

4. Provide copper strip slitting machine line spare parts and wearing parts all year round