- PRODUCT DETAIL

High-Efficiency Color Steel Roof Panel Roll Forming Machine for Superior Roofing Solutions

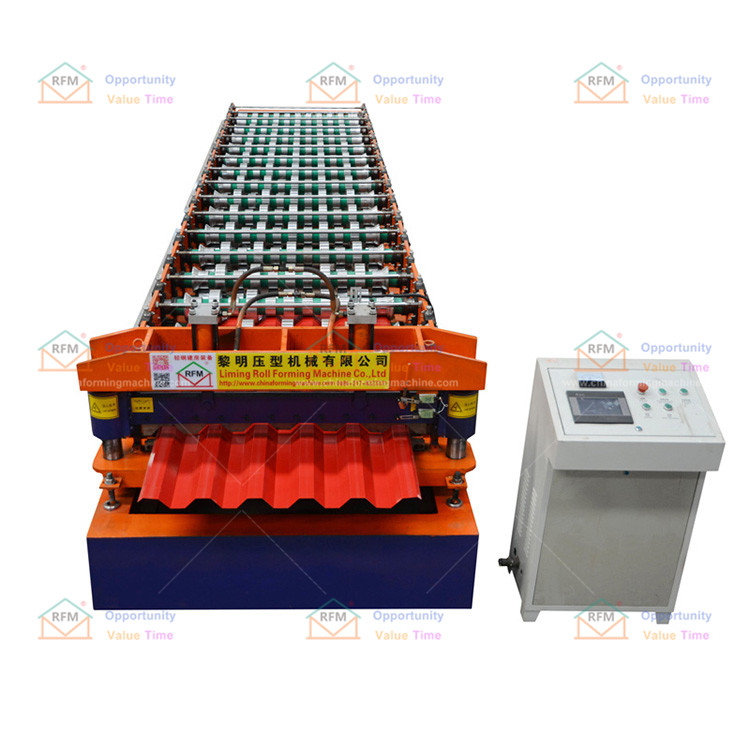

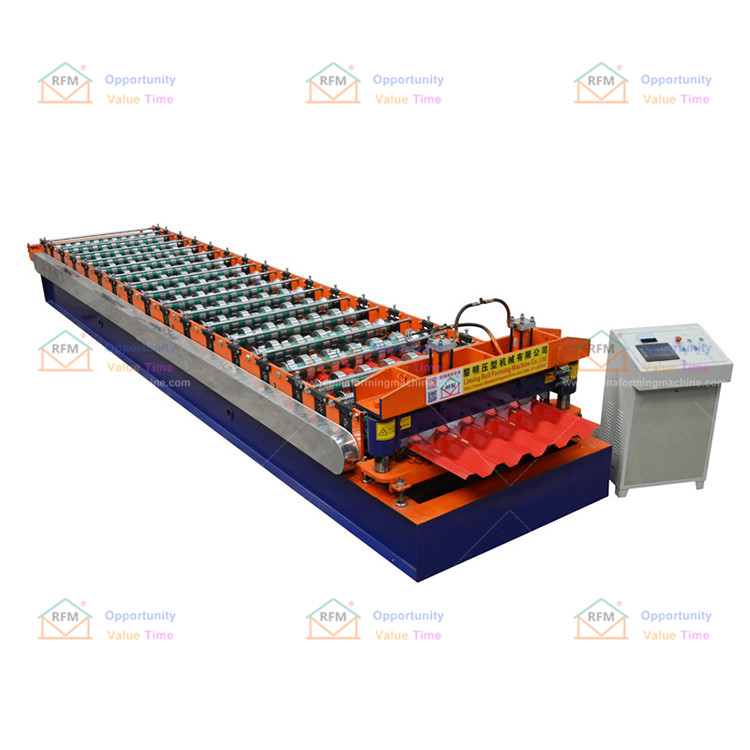

The Color Steel Roof Panel Roll Forming Machine consists of an unwinding machine, a forming machine, a cutting machine, an electronic control system, and a hydraulic system. The products produced have a smooth and beautiful appearance, uniform paint texture, high strength, and durability. Widely used in industrial and civil buildings, such as factories, warehouses, machinery garages, hangars, and sports stadiums.

The color steel tile machine equipment adopts advanced automatic control software to achieve production information management. The entire unit’s automatic control system adopts a highly integrated network, making the performance of the automation system more superior.

The color steel tile press equipment also has operation, maintenance, and advanced automatic control software to achieve production information management. The entire automation control system of the unit adopts a highly integrated network, which makes the performance of the automation system more superior. The color steel tile machine equipment also has the advantages of easy operation, maintenance, upkeep, mechanical debugging, and mold replacement.

From the perspective of market share, with the popularization and application of color steel tile machine, many large industrial and mining plants, warehouses, steel roof Truss and large equipment now use color steel tile, or color steel equipment, or even glazing. The color steel tile machine equipment makes the appearance of our living buildings more colorful, beautiful and tidy. These colored tiles are pressed by the color steel equipment (professional name: cold bending forming equipment) of the tile press.

The steel plate enters the color steel forming equipment, and is pressed into various types of plates by various pressure rollers, and then cut and processed into suitable plates that can be used.

Application Range & Scene

Recently, many customers have been choosing polyurethane roof panel production lines. This product is insulated, easy to install, and suitable for use in many places. If you are interested, please contact us

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

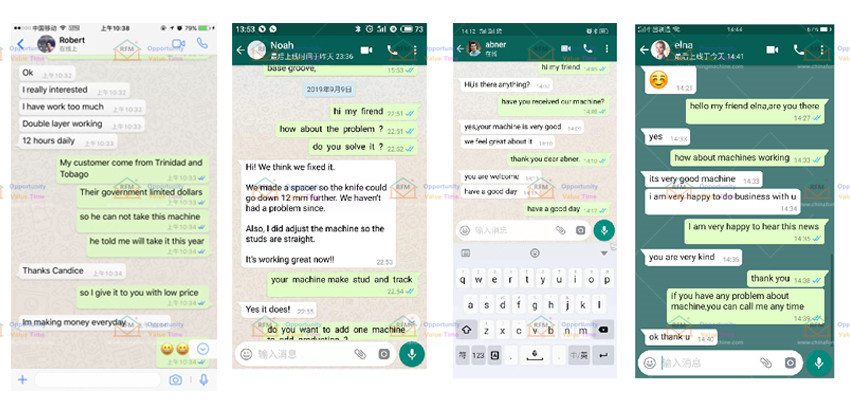

Customer Feedback

FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn’t just provide a few photos to prove what they can produce

2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don’t show the product I need, can you manufacture it?

Our company’s engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life.

The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

1. Give me the dimension drawing and thickness, it is very important.

2. If you have requirements for production speed, power, voltage and brand, please explain in advance.

3. If you don’t have your own outline drawing, we can recommend some models according to your local market standard.