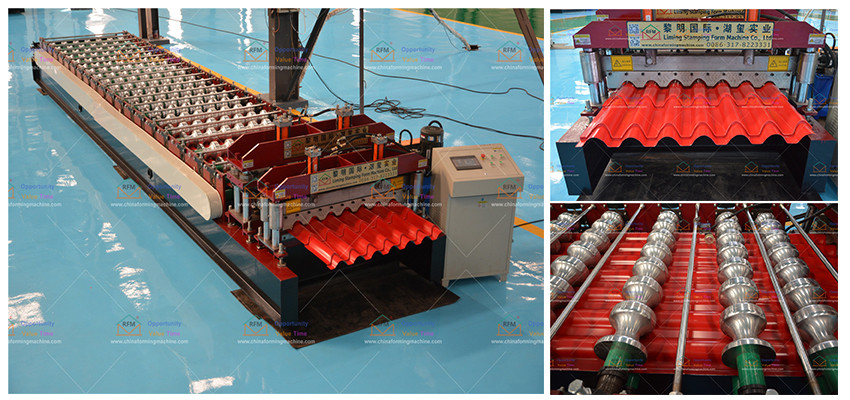

1. The structure is beautiful in appearance. Because the whole machine adopts H-shaped steel structure, the overall processing after welding, the structure is simple and reasonable, the storage capacity is strong, the operation is stable and reliable, and the performance is guaranteed.

2. High degree of automation, fixed-length cutting, fixed-length positioning, beautiful and tidy head and tail, no deformation.

3. Applicable to wide-width board forming, beautiful forming, production speed of 15-20m/min, high utilization rate of raw materials, and high precision of fixed length.

4. It has excellent characteristics such as low thermal conductivity, low fault tolerance, good thermal insulation molding, low noise and long life.

5. The fire protection design highlights the ingenious design and design. The surface information and insulation material of the black composite board are non-combustible materials.

6. The splicing installation can choose the cutting point of the composite board at will, to ensure that the error during cutting is controlled within the minimum range, no manual operation is required, and the work efficiency is high.

7. The installation, commissioning and maintenance are simple and convenient, and the design and structure are rigorous. The whole machine adopts an automatic lubrication system to ensure smooth operation.

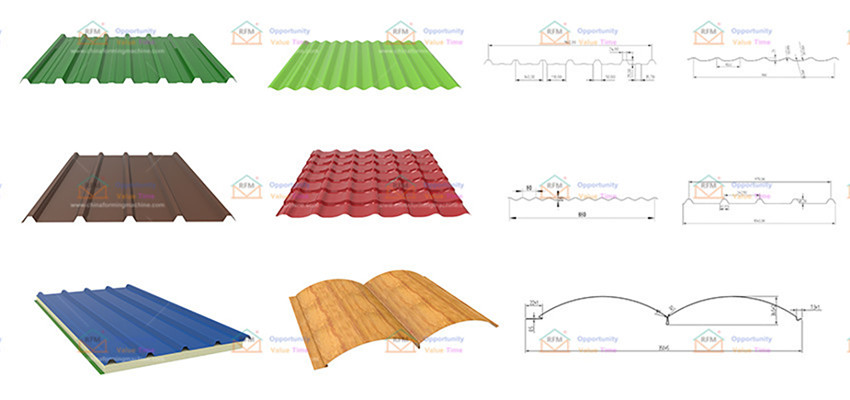

Applications:

The large-scale car body version forming machine can be used for various types of vehicles such as automobiles, electric vehicles, agricultural tricycles, etc., mainly used in the production of profiles such as car beams, car panels and window edges, and also supporting the production of car car pillars, car bottom crossbeams, and car floors Side beams, car left-right-rear panels, car front baffles, etc.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

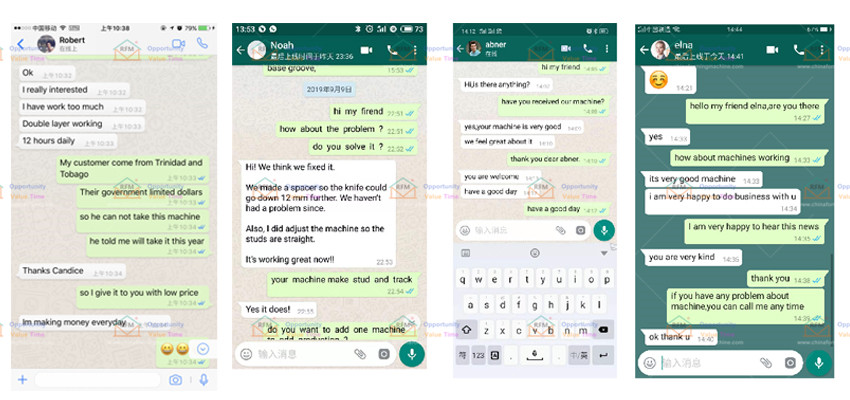

Customer Feedback