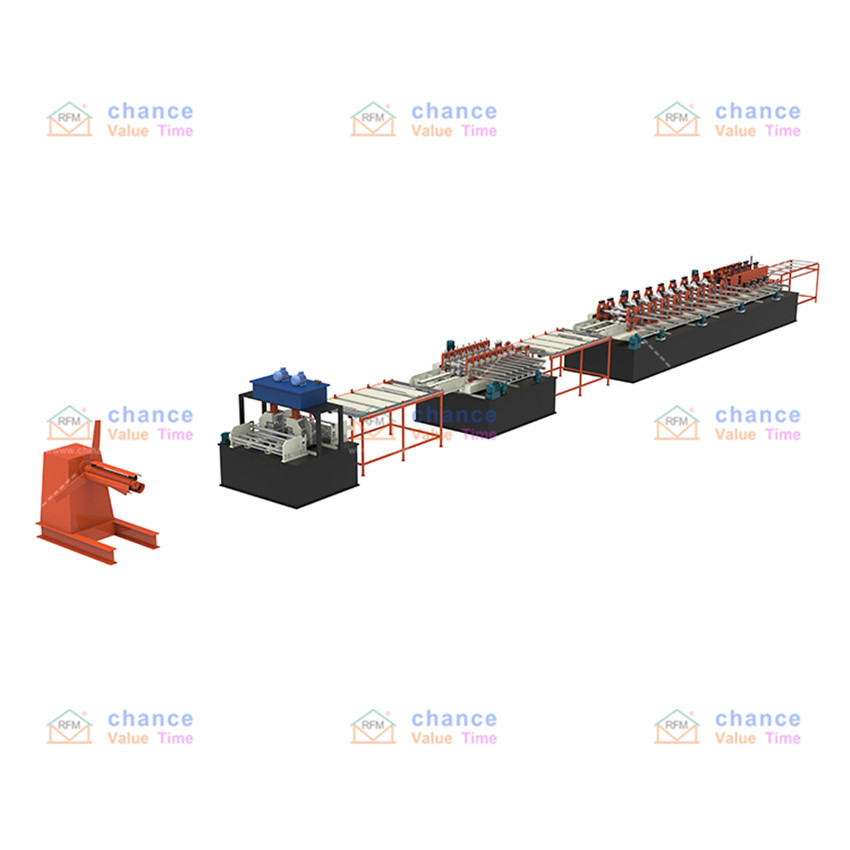

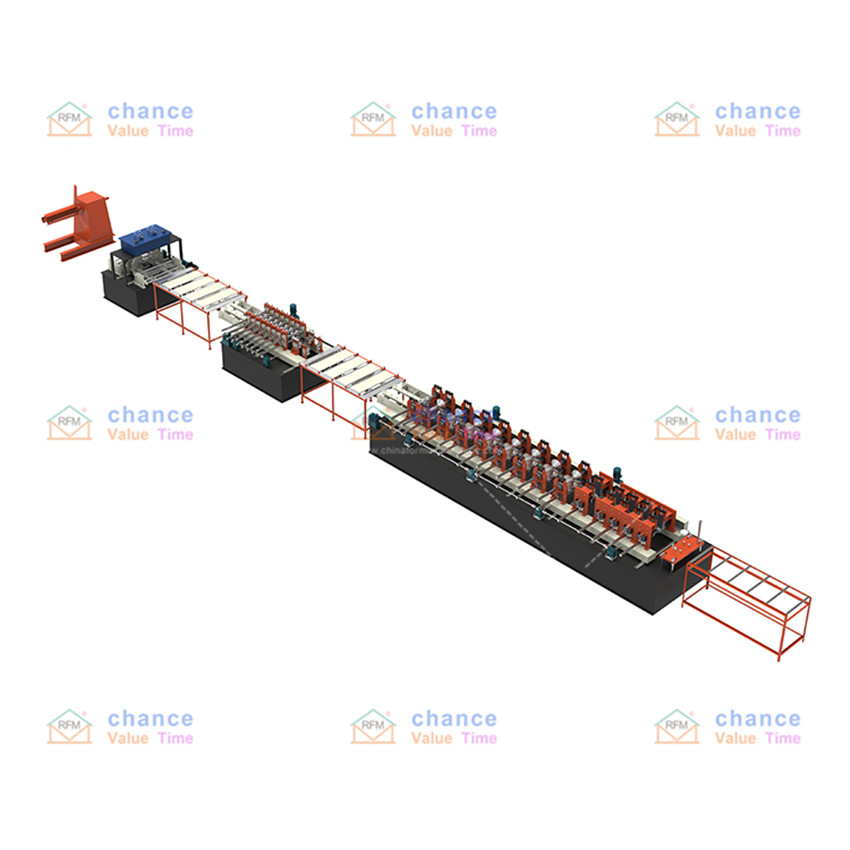

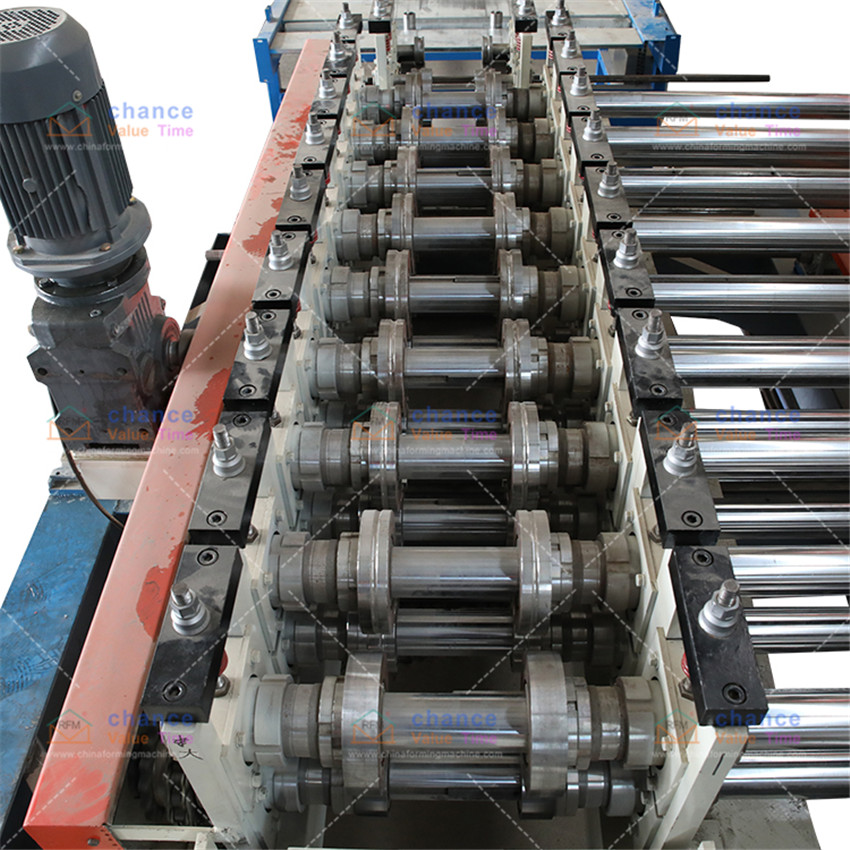

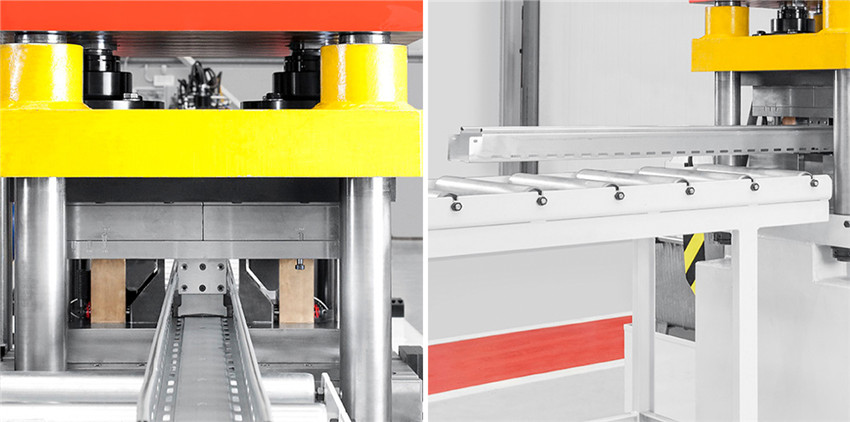

I recently met a customer from Australia,Mr. Jacky,he want to purchase a cable tray roll forming machine. Due to the relatively high labor cost in Australia, he wanted a machine with a higher degree of automation. And want a machine with a higher safety factor. I introduced our machine to him. Our metal cable tray roll forming machine can produce cable trays of different specifications. The roll forming machine adopts a combination adjustable type. A set of rollers completes all specifications of bridge products. The specifications can be adjusted automatically. The forming process includes uncoiling → leveling → pinch feeding, punching → forming → length determination, cutting →receiving, high degree of automation, not only high production efficiency, but also saves labor and reduces labor costs. And our equipment control is PLC control, the control is more precise, the equipment operation is also more precise, and the error rate is reduced. In addition, a detachable protective cover is adopted on the periphery of the equipment, which not only protects the chain but also protects the safety of the workers, and prevents the workers from being caught in the machine when operating the machine, causing hidden safety risks.

The plug configured in our electronic control system is also an aviation plug and will not fall off easily because of the kick. The connection is tight to avoid the risk of leakage. Pay attention to the details of the equipment to ensure the safe operation of the machine without causing unnecessary trouble to customers. Our machine fully meets the customer’s demand for high safety factor and labor saving, and we have reached a pleasant Cooperation.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

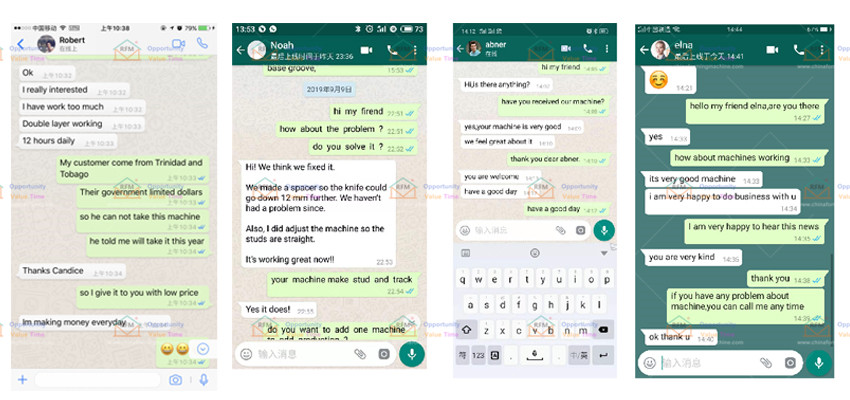

Customer Feedback