1. What is a cable tray?

The cable tray is used to protect the cables, and the cables are placed inside to play a protective role; the cable tray is specially used for laying large-diameter cables, and the wires are laid in the trunking. Therefore, cable trays usually appear in some environments with high security requirements.

The appearance and shape of the cable tray and the galvanized trunking are the same, but the specifications and dimensions are different.

The width of more than 200mm is “cable tray”; the width of less than 200mm is “galvanized wire trough”

2. What is a metal wire slot?

The shape of the metal wire trough is the same as that of the trough type cable tray, but the size of the metal wire trough is slightly smaller and the material performance is different.

Wire troughs, also known as wire troughs, wiring troughs, and wire troughs (different from place to place), are electrical appliances used to standardize power lines, data lines, etc., and fix them on the wall or ceiling. Wire troughs can be divided into insulated wiring troughs, open wiring troughs, mini wiring troughs, separated wiring troughs, interior wiring troughs, integrated insulated wiring troughs, telephone wiring troughs, and Japanese telephones Wiring ducts, open wire wiring ducts, round wiring ducts, exhibition partition wiring ducts, round floor wiring ducts, soft round floor wiring ducts, cover type wiring ducts, etc.

Third, the difference between cable tray and metal trunking

1. The general width of the cable tray is >200mm, and the width of the metal slot is less than 200mm.

2. The cable tray is mainly used for laying cables, and the metal trunking is mainly used for laying wires.

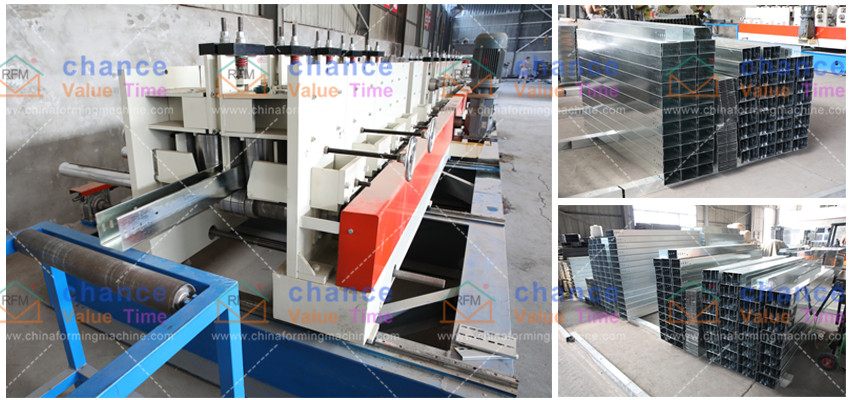

3. There are many types of cable trays, such as ladder type, trough type, tray type, combined type, etc. In terms of material and anti-corrosion treatment, it is divided into aluminum alloy, glass fiber reinforced plastic, cold (hot) rolled steel plate galvanizing, spraying, etc. There is only one type of metal wire groove, which is generally made of hot-rolled steel plate.

4. Generally, the load, deflection and filling rate of cable trays should be considered when laying

5. The metal trunking is approximately equal to the trough-type cable tray, but some metal trunking is smaller in size (except for ground trunking). Some wires that need to be connected to the power distribution cabinet from the bridge are all walked into the metal wire trough and then connected to the power distribution cabinet.

6. There are many kinds of bridges, which are open, and most of the cable ducts are closed (plastic & metal)

7. Two laying methods with different current carrying capacity

8. Generally, the quality of the bridge frame is cold-rolled steel plate, and the wire groove is made of galvanized iron.

9. In terms of appearance and material: My point of view is that the cable tray is thicker than the metal trunking, and the installation is relatively firm.

10. Cable trays are generally used in the construction industry, and metal trunking is more commonly used in the general decoration industry.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

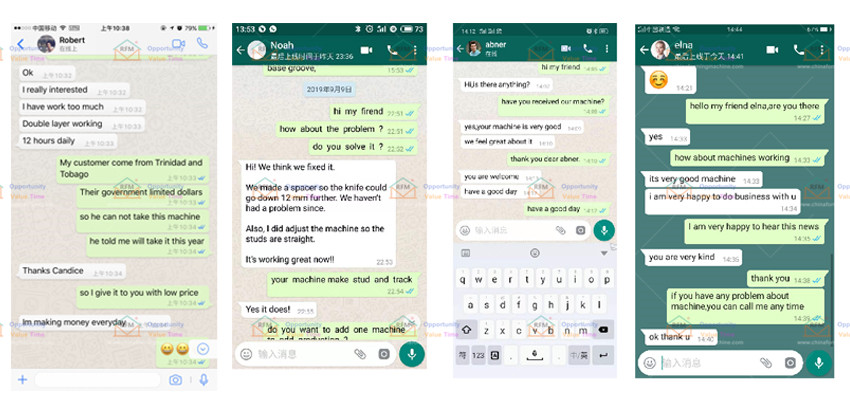

Customer Feedback