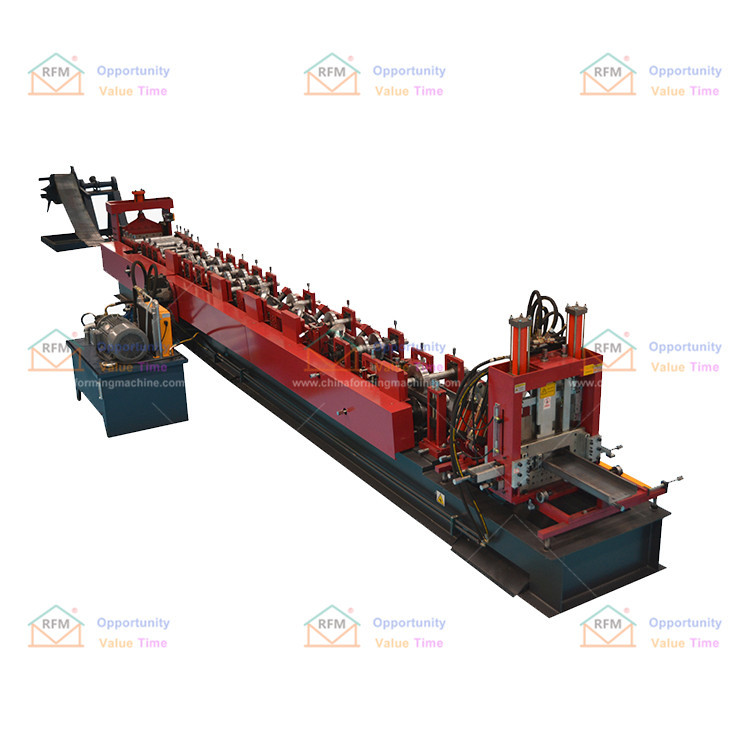

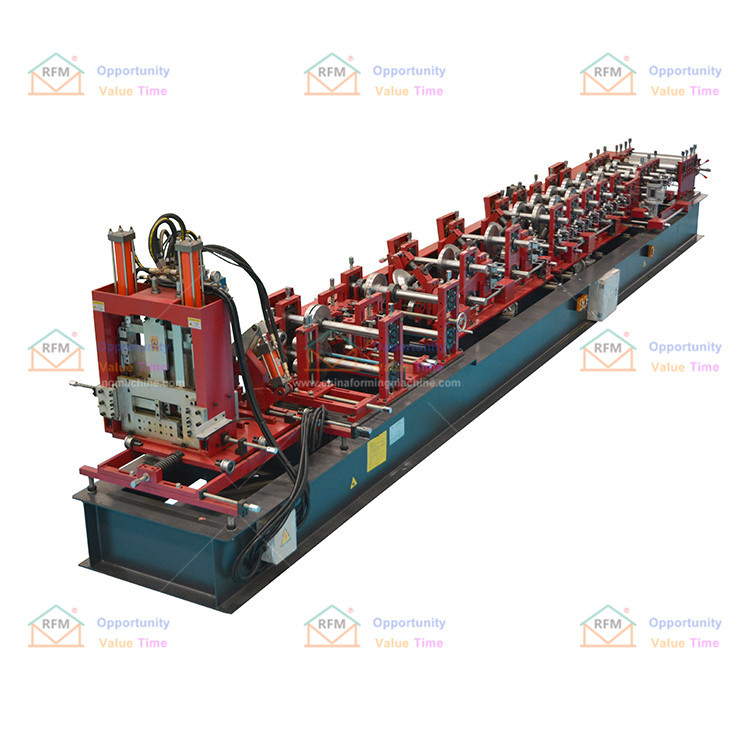

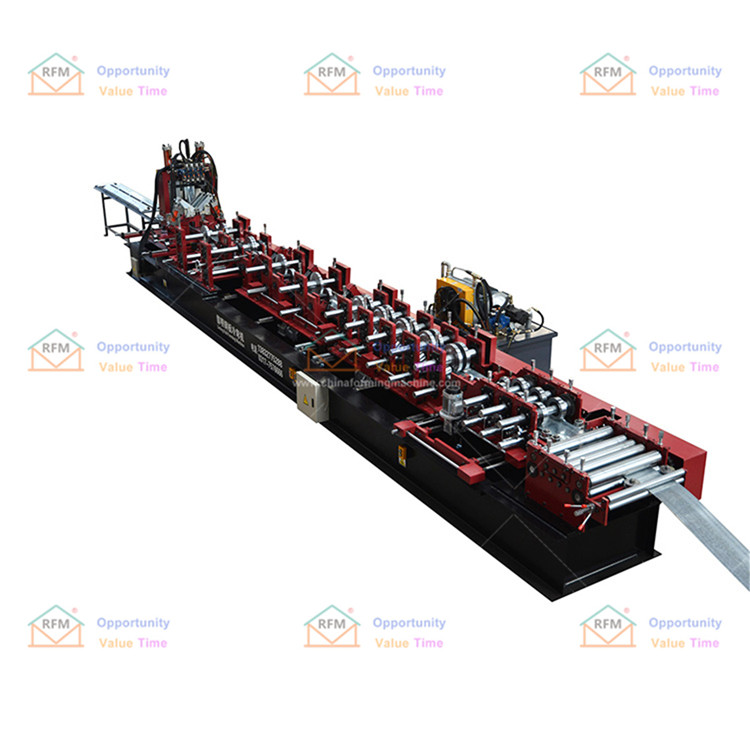

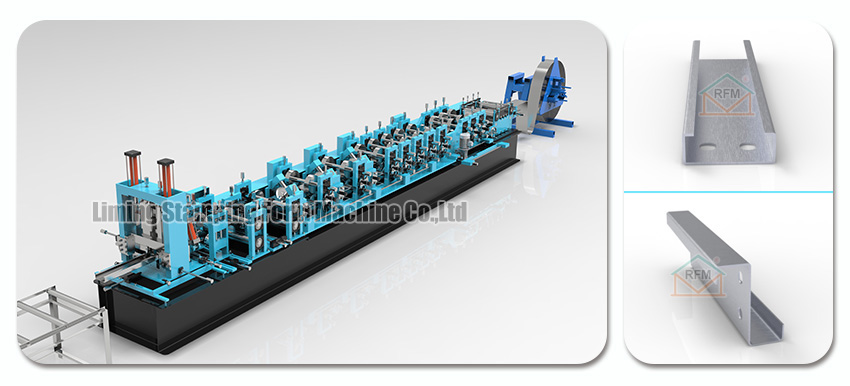

Hot Selling Fully Automatic C/Z Purlin Roll Forming Machine Manufacturer

Mr. Anton from Zambia wants to buy a C/Z Purlin Roll Forming Machine and found our Liming roll forming Machine Co., Ltd. on Google.

We can provide a C/Z Purlin Roll Forming Machine with stable stability, excellent workmanship and simple operation, which solves the production difficulties caused by the complicated operating system of the workers during the use process and meets the requirements of Mr. Anton who wants to hire low labor.

Mr. Anton had doubts about our wheels. What is the difference between C12 wheels and ordinary wheels? I watched Mr. Wheel’s destructive experiments on wheels, and explained to Mr. C12 the benefits of C12 wheels for machine products, because We are a cold bending industry, we mainly rely on the hardness of the wheel and his process to squeeze this sheet to achieve the shape the machine wants to produce, so for our product machine, the hardness of the wheel is a factor that can determine its use One of the factors that lasts for a long time, of course, we can’t see it from the surface. Our wheels can really be tested. After all, no one wants to buy back a lot of scrap iron at a high price. Mr. Anton was very satisfied with our machine.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

—Product packaging & transportation—