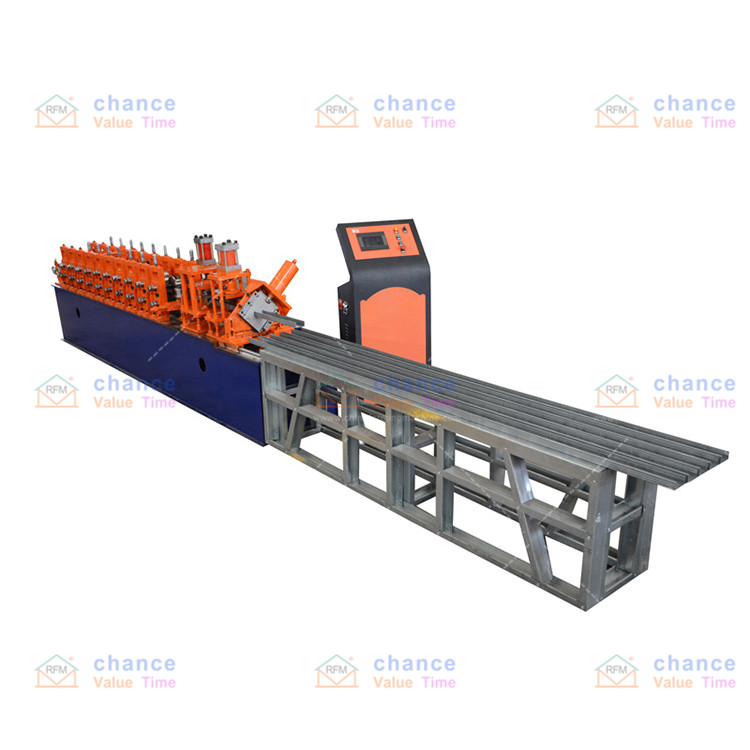

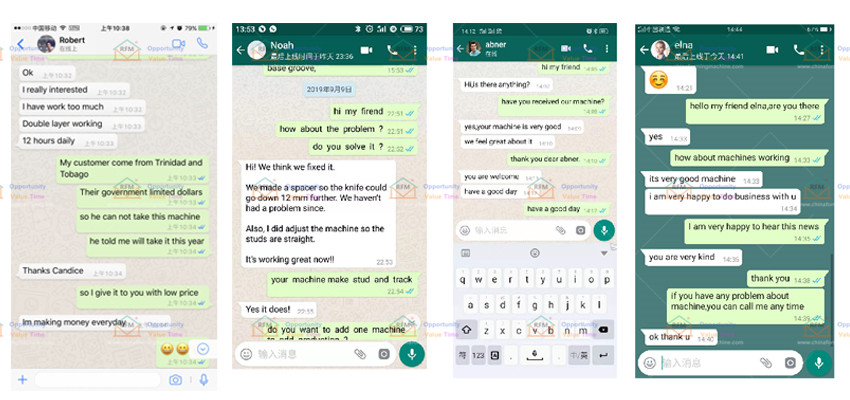

Johnson from the United States visited our factory in early June. Under the leadership of our staff, he visited our well-ordered production workshop, and further visited the new C-shaped keel roll forming machine that he ordered that can produce studs and tracks. This machine combines the advantages of traditional keel equipment. It adopts the national standard 360 heavy-duty I-beam with CNC precision technology. The color of the body can be customized according to customer requirements; all rollers are made of solid and durable materials, which are not easy to wear and can Long-term use is guaranteed; the patented Mengniu archway uses “double” bearing technology, low-noise GCr15 material, and the service life can be up to 20 years. With more than 20 years of experience accumulation, all parts and components on our equipment come from first-line brands at home and abroad, and are high-quality products certified by ISO and CE. The equipment’s software system comes from an international general operating system, which can be selected according to the user’s local language and adopts customized operation settings to achieve a strong combination of hardware and software, and enhance the good experience of use and operation. Regarding the raw materials processed by the C-shaped keel roll forming machine, Johnson told me to use 0.6mm thick galvanized steel coils. Of course we can do it for him, because the thickness of the raw materials processed by our equipment is generally 0.3-0.8 mm. Of course, if you have other needs, you can also contact us. We can customize it according to customer requirements. Johnson is very happy to hear it. In the QC quality inspection link, Johnson was very surprised by the strict inspection process of our quality inspectors. Each part has to go through multiple inspection tests before being applied to the equipment. Johnson is full of the quality of our equipment in confidence. Through this day’s visit, Johnson said that this trip was very interesting and he looked forward to coming to China next time.

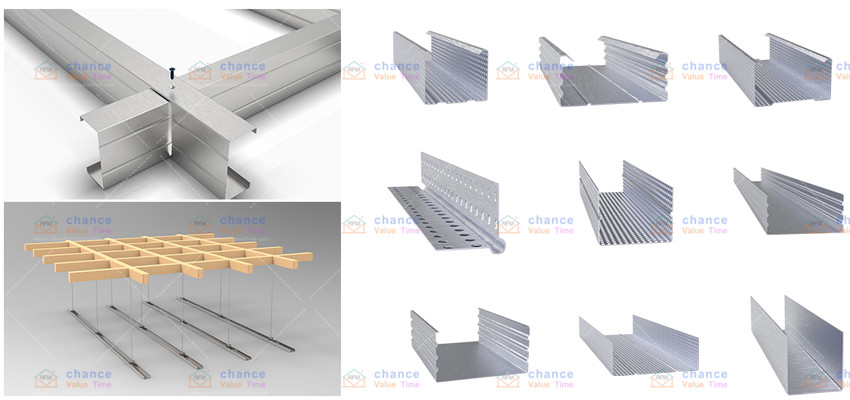

C-type keel roll forming machine Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery