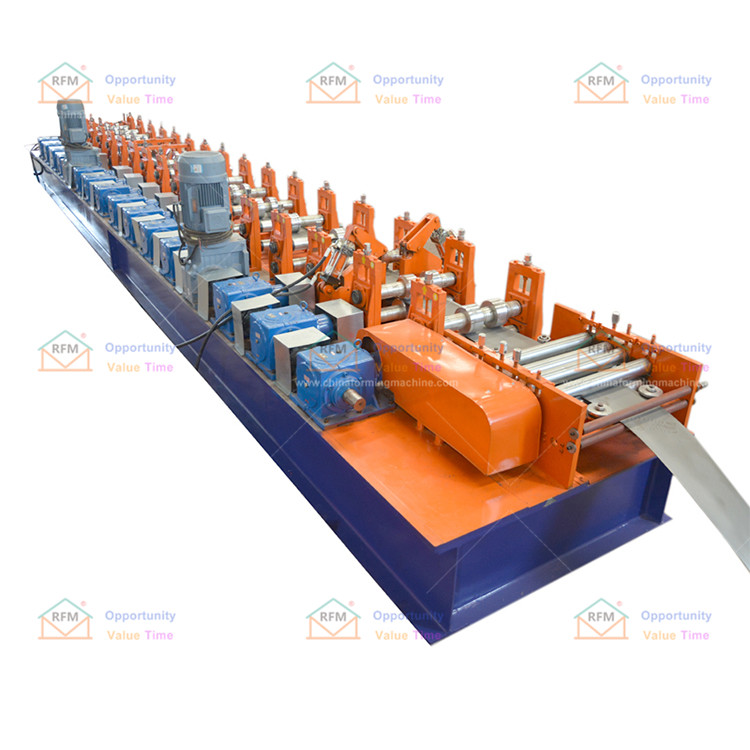

Fully automatic c purlin roll forming machine

The C-shaped steel is automatically processed and formed by the c purlin roll forming machine. The machine can adjust the bottom width. The products are often used in steel structure houses and steel structure workshops.

The forming process of the C purlin can be automatically adjusted by the C purlin roll forming machine according to the set size.

Advantages of c-type purlin roll forming:

1. No need to change shape, simple operation

2. Compared with the price, the fully automatic CZ purlin forming machine is much cheaper

3. The bottom width can be adjusted

The automatic C purlin roll forming machine can reduce labor costs and save corporate resources; we provide detailed versions of drawings, and assign our professional design team to design and produce 3D drawings.

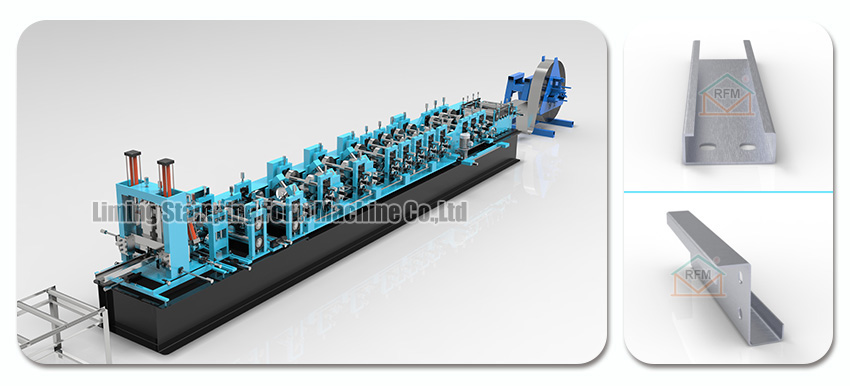

If you have demand, the machine can also produce two models C and Z.

We know that the channel steel is produced by hot rolling, and the thickness is relatively large, and it is directly supplied by the steel mill. However, C-section steel is produced from cold-rolled strip steel (although it is also hot-rolled now), which is thinner than channel steel and is generally supplied by steel mills.

And judging from their classification, there is also a big difference. Generally speaking, channel steel can be divided into ordinary channel steel and light channel steel. The specification of hot-rolled ordinary channel steel is 5-40#. Hot rolling process provided by agreement between supplier and supplier.

—C purlin roll forming machine —

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

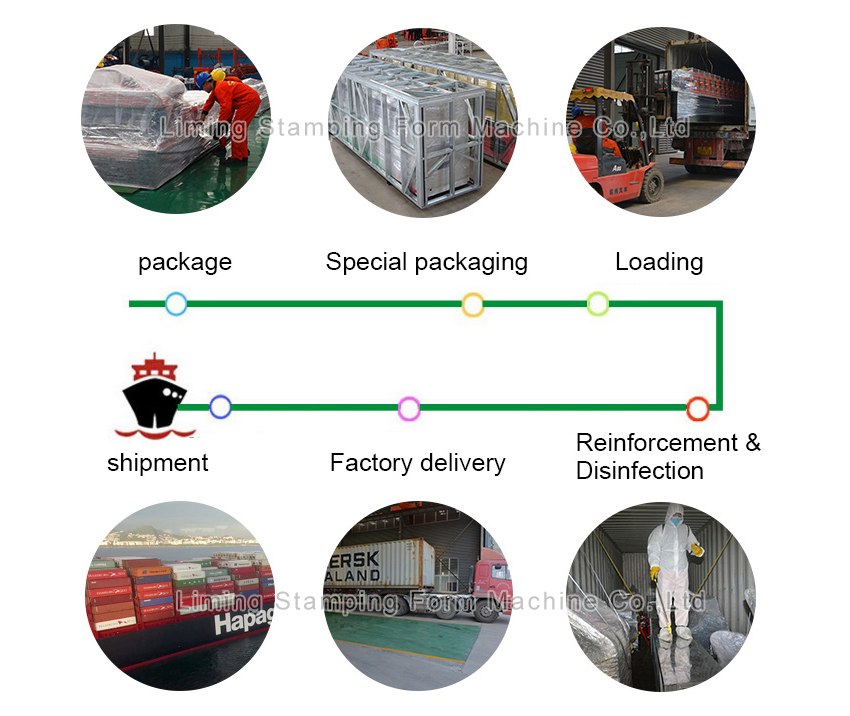

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—