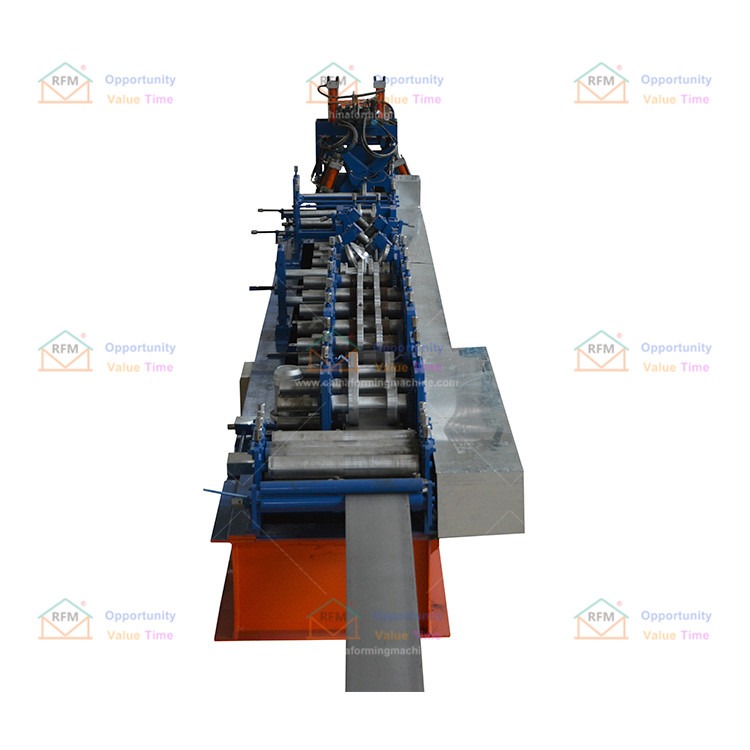

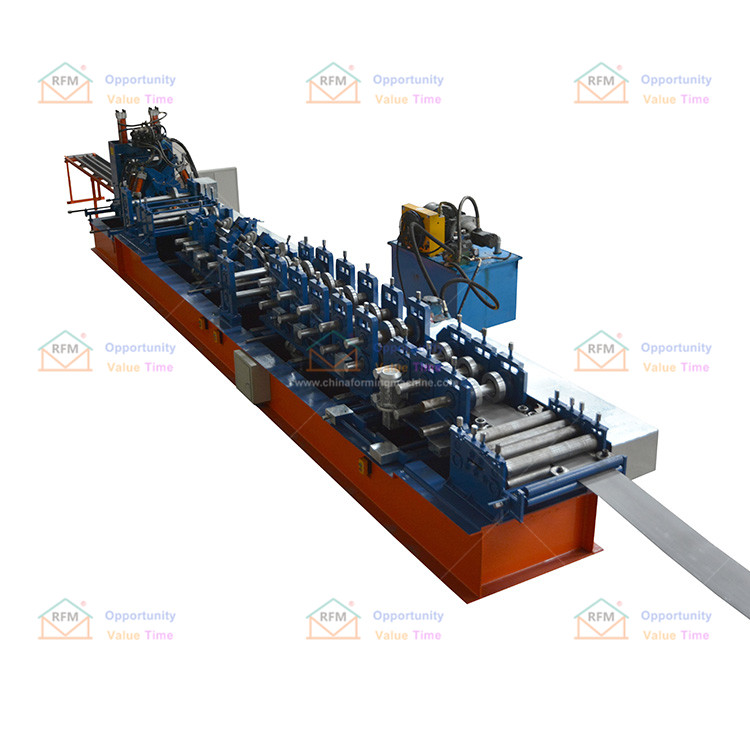

C channel purlin forming machine – factory price

For steel structure house builders, the long service life of the C channel purlin forming machine is a very important concept.

I met a client from South Africa, Bestbuymetals, a manufacturer of building materials in the housing construction industry. He received a project to build a 2000 square meters steel structure workshop. Because C-shaped purlins are needed to build the house structure, only the C-channel purlins are in good shape and are not easily deformed in order to meet the quality standards and ensure their service life. In the past project, because the C-channel purlin molding process was immature, it could not meet his needs for long-life houses.

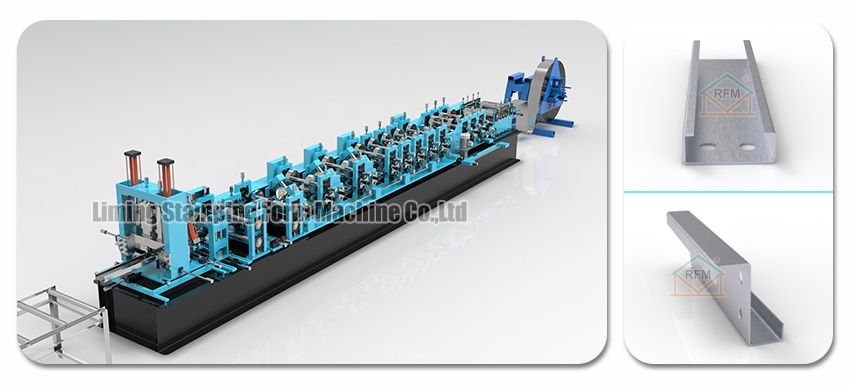

We provided him with a C channel purlin forming machine for building structure construction. Our raw materials are purchased from large domestic steel plants. Large domestic steel mills attach importance to quality and reputation, so they can ensure that the raw materials used to manufacture roller parts are steel and chromium, and they can meet the standards through quality inspections. Can meet the needs of quality standards.

Our molding process is designed by copra software and supported by data, which can ensure that the shape of the purlin is intact and not easily deformed during molding, and improve the service life of the C channel purlin molding machine.

Advantages of C channel purlin forming machine:

1. The forming thickness is large, the highest can reach 4mm

2. CZ purlin interchangeable model machines can be upgraded

3. Front shearing system, more accurate size, no waste

4. Bottom width can be adjusted

C channel purlin forming machine video

Later, Mr. Bestbuymetals continued to occupy the market share through the machines we provided and improved economic efficiency. We also became a happy partner.

—CZ purlin roll forming machine—

| No. | Item | Specification |

| 1 | Can Formed Material | GI,AI |

| 2 | Equipment operation | Automatic |

| 3 | Voltage | 380V 60Hz 3Phase or as your requirement |

| 4 | Thickness of sheet (mm) | 0.3-0.7mm |

| 5 | Material width(mm) | As your requirement |

| 6 | Cover Width of the sheet after formed | as your drawing |

| 7 | The size of the roll forming machine | 5500mmx1200mmx1400mm |

| 8 | Speed | 12-15m/min |

| 9 | Diameter of shaft | 40mm |

| 10 | Weight of the Machine | 2200-2500KGS |

—6 major production plants—

—25-36 inspection process—

—Serving 156 countries—

—Multiple national certiffication—

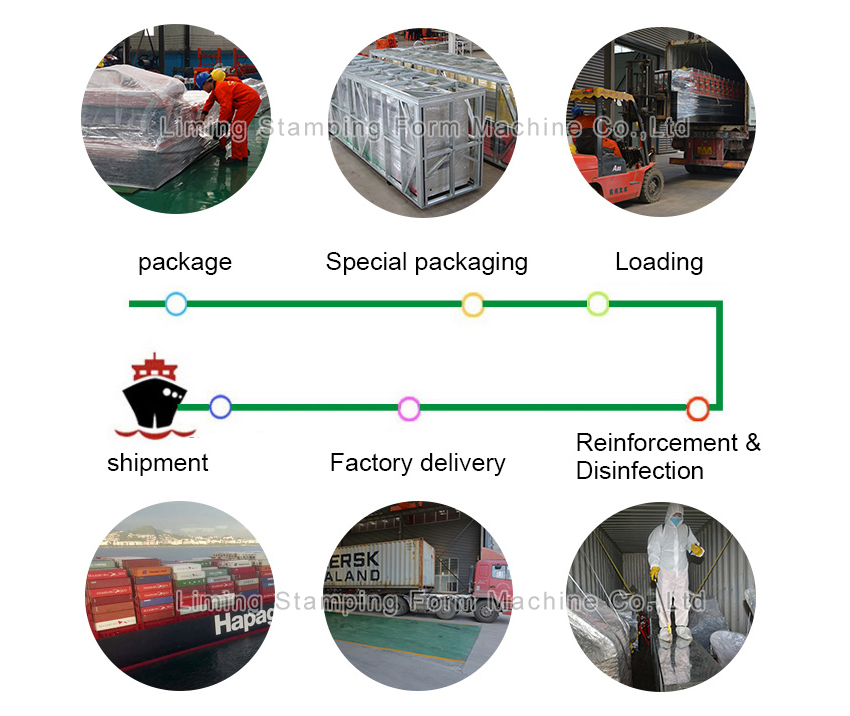

—Product packaging & transportation—