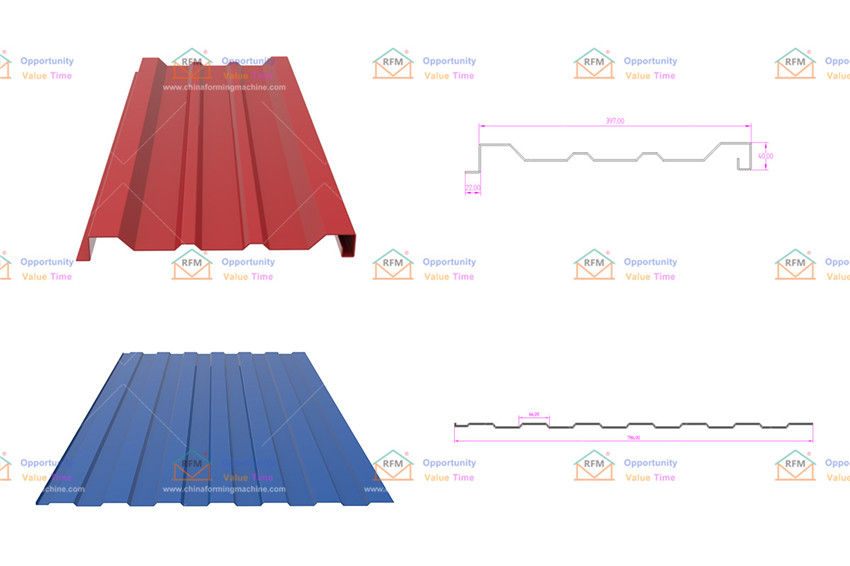

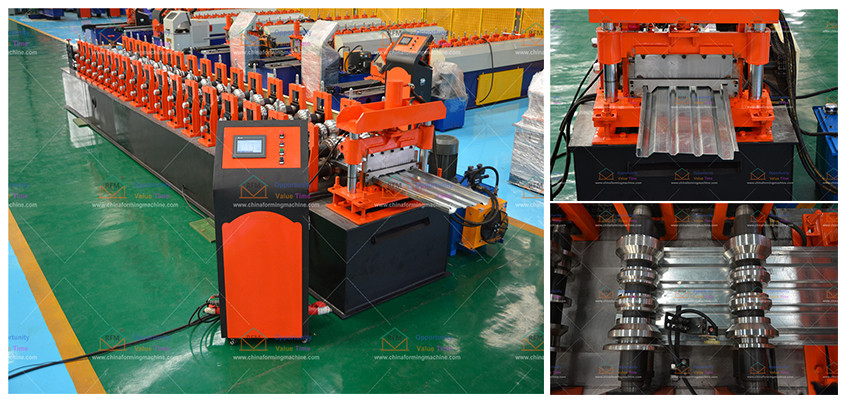

The forming part of the carriage plate machine:

The roll forming system is composed of a frame, transmission components and cold-bending forming roller wheels. It is divided into Seiko-style wheel rotation forming, which has good forming effect, reduces friction between wheels and raw materials, and is convenient and fast to debug.

Workflow of carriage board machine:

Uncoiling-guided feeding-roll forming-fixed length cutting-finished product exit

Manually fix the workpiece, manually roll up, enter the PLC operation page-press the “start” button-automatic entry of the plate-start according to the set program-cut off after reaching the set size, the device automatically The pressing plate is completed.

The shape and surface quality requirements of the steel plates used in the manufacture of automotive cabin equipment mainly include the following: the surface must not have defects such as cracks, bubbles, scars, folds, scratches, oil stains, rust, etc. If there are some minor defects mentioned above, Allowed, but its depth cannot exceed half of the negative tolerance; the steel plate must not have any internal lamination, the edges a

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

Customer Feedback