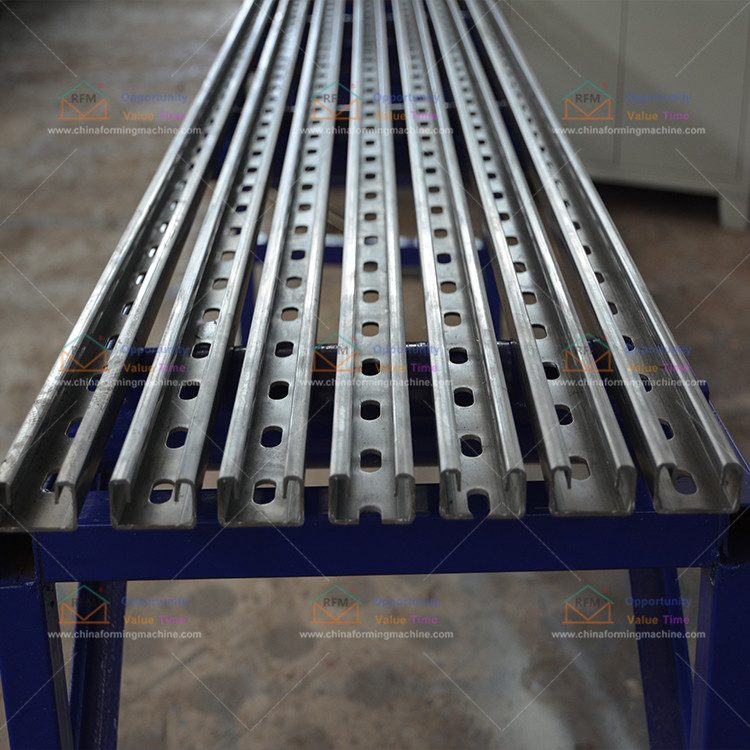

Automatic pv stents cold bending forming equipment by manually adjust or change several groups of roll production requirements for the different specification, can be achieved by the roller mould adopt numerical control lathe processing, production process is treated by high temperature quenching, Cr12 material die wheel, fine, fine grinding, plated collaterals, such as processing, the roller wear well, wear resistance, long service life.High precision mold cold forming, maintain the appearance of the finished product, no sliding paint, achieve low wear!

Automatic solar photovoltaic bracket press machine equipment is mainly composed of uncoiling device, feeding guide platform, online punching device, roller forming machine, cutting device, discharge frame, hydraulic system, electrical control system and other parts.It is characterized by reasonable structure, simple operation, reliability, short production process and wide application.

The roller die of the automatic photovoltaic bracket cold bending forming equipment is processed by CNC lathe, the production process is processed by high-temperature quenching, Cr12 material mold wheel, fine car, fine grinding, plating hard and other processing, the roller is durable, anti-wear, long service life!

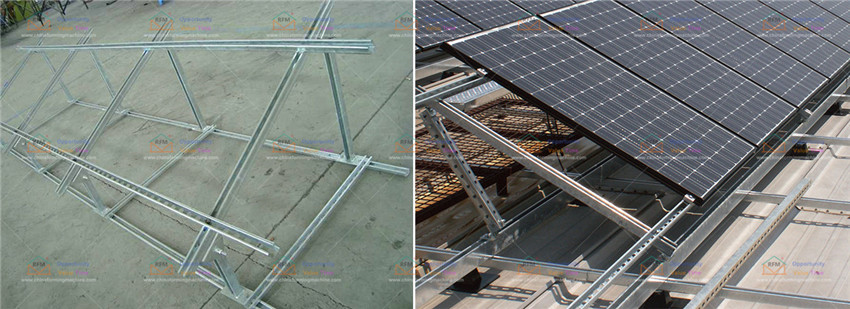

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

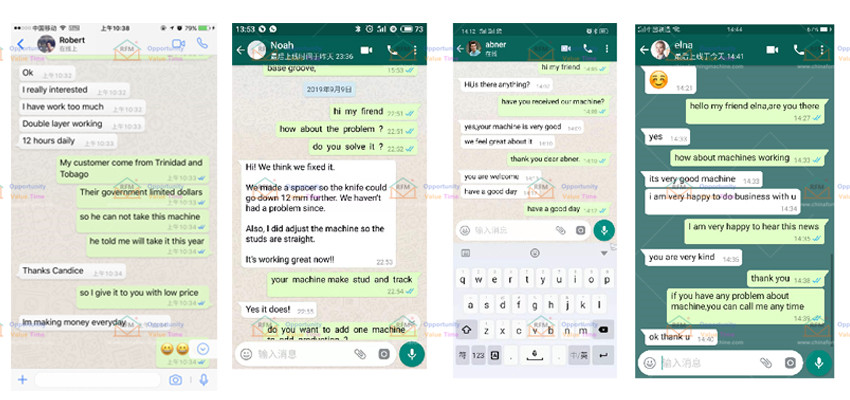

Customer Feedback