The basic components of the slitting line production include the electrical control system. The sequential operation of the electrical air system of the slitting and slitting machine is controlled by the PLC program of Japan Omron Corporation, so as to realize the sequential control of the entire line. Electric control console: Three electronic control operations required for slitting equipment, one-stop operation of full line control, line speed adjustment. The application of numerical control technology further improves the slitting speed and precision of slitting production lines, and greatly improves the production efficiency of customers who produce slitting equipment.

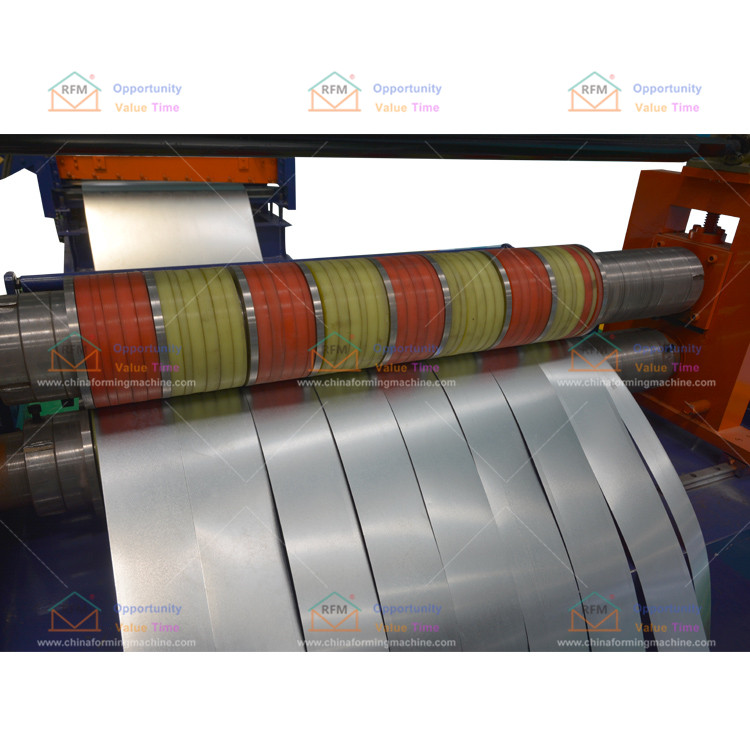

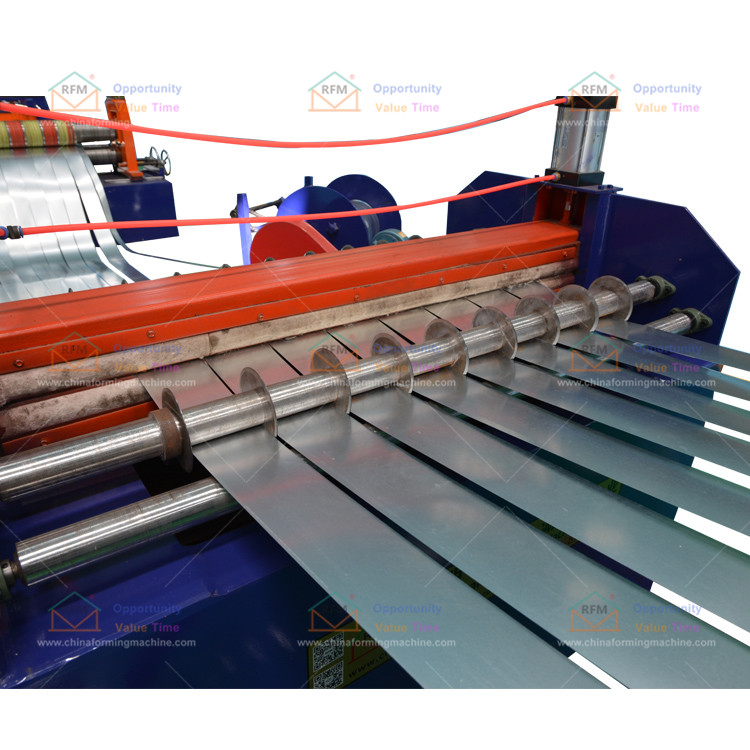

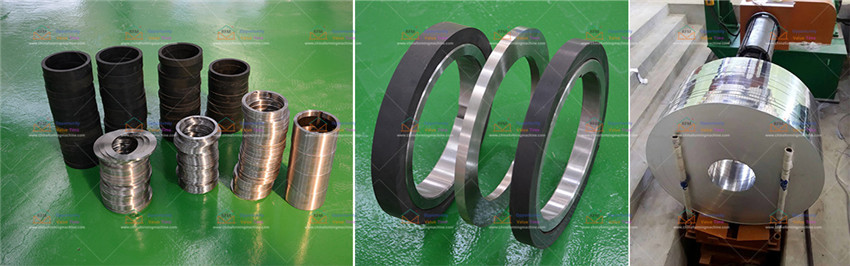

Fully automatic longitudinal cutting slitting lines are designed and manufactured according to customer requirements, and can be customized to cut longitudinal slitting production lines with different numbers and thicknesses. The slitting line equipment consists of: raw material unwinding support (10T) → leveling → longitudinal cutting → collecting edge material → pneumatic pressing device → automatic winding machine

1. The slitting line is a thin-plate slitting production line, which can be customized with a thickness of 0.1-3.0mm

2. The material of the slitting line can be processed with: color steel plate, steel strip, stainless steel, cold plate, silicon steel, tinplate, etc.

3. The slitting line is a fully automatic slitting device, and the entire line is processed automatically, without the need for excessive manual participation.

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

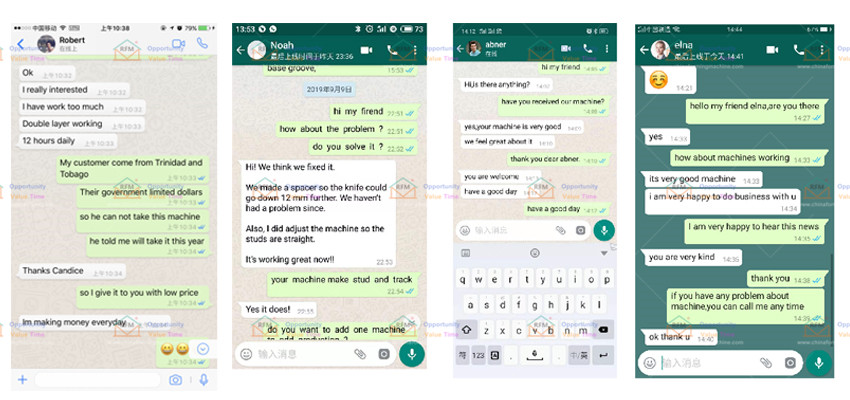

Customer Feedback