Mki Mko comes from an Egyptian company specializing in the production, sales and installation of Australian-style roller shutter doors. He contacted us via Facebook. He hopes that we will provide him with a new Australian-style rolling shutter door manufacturing machine to meet the rapidly growing market demand. He explained to us that he needed to print the company logo on the shutter door connecting piece, and he also needed an edge banding machine and a packaging machine to roll the produced connecting piece into a shaft to facilitate sales and transportation.

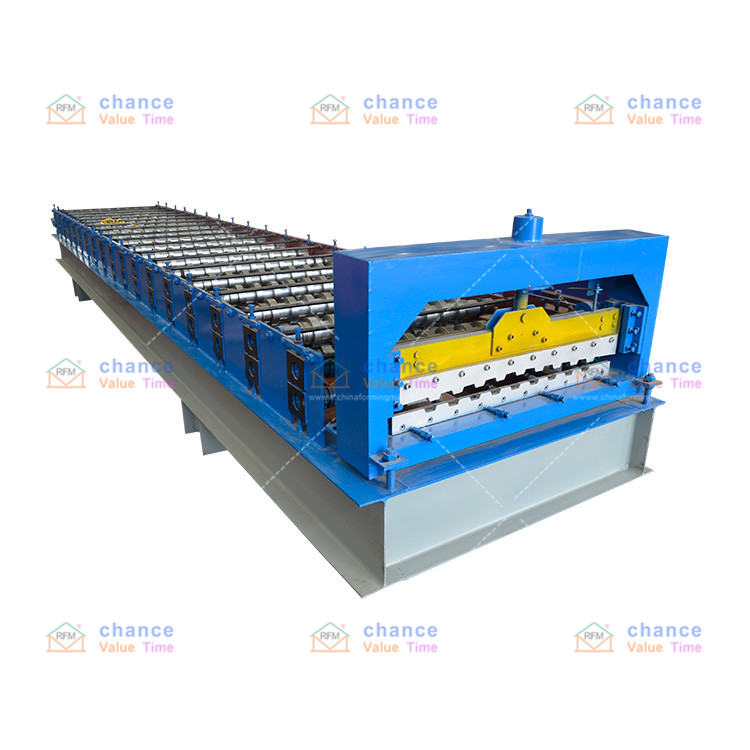

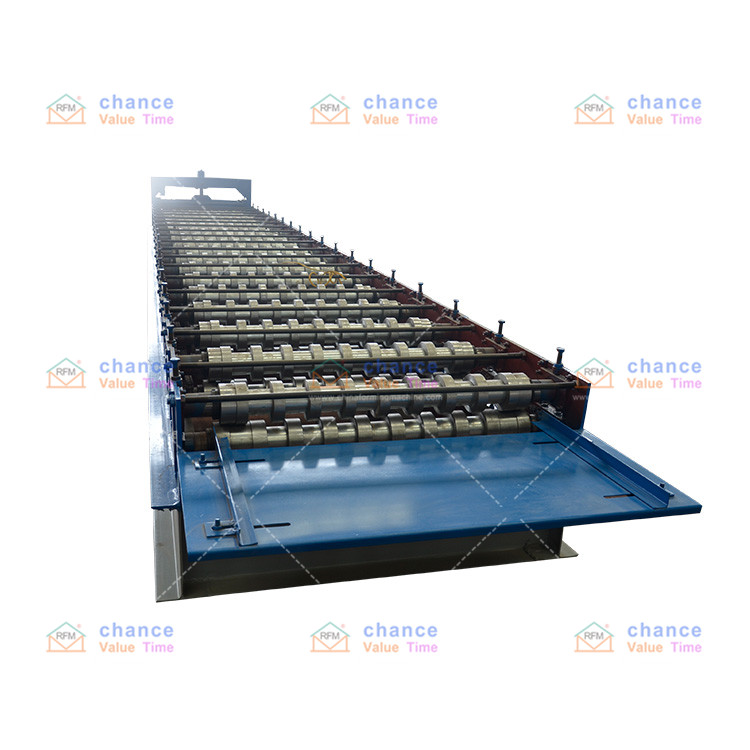

We first equipped him with an electric uncoiler to increase production speed. We added a punching machine to the molding machine to print the company logo as needed. In order to better connect the continuous pieces, we are equipped with a 6 meter seam machine, which has a fast processing speed. According to customer requirements, packaging machine is not a standard machine, there is no special factory to produce, need to design and then produce. Our engineers and design team spent two days to make the structural drawings and installation drawings of this machine. Mki Mko was very satisfied after reading the drawings. We have equipped the hydraulic system of the machine with an air cooling system. Even if the machine works continuously for 12-15 hours, it will not stop production due to excessive oil temperature, which greatly improves the production efficiency of customers. We added an outer layer of galvanized iron wire mesh protection to the oil pipe to avoid the phenomenon that the oil pipe bursts and hurts the worker when the pressure is too high.

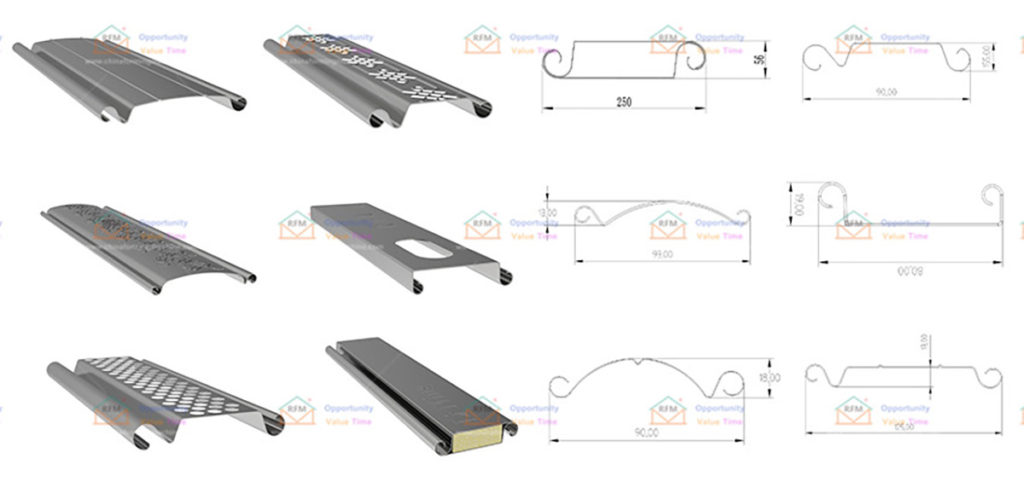

Application Range & Scene

Provide Installation Method & Customized Profile For Free

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

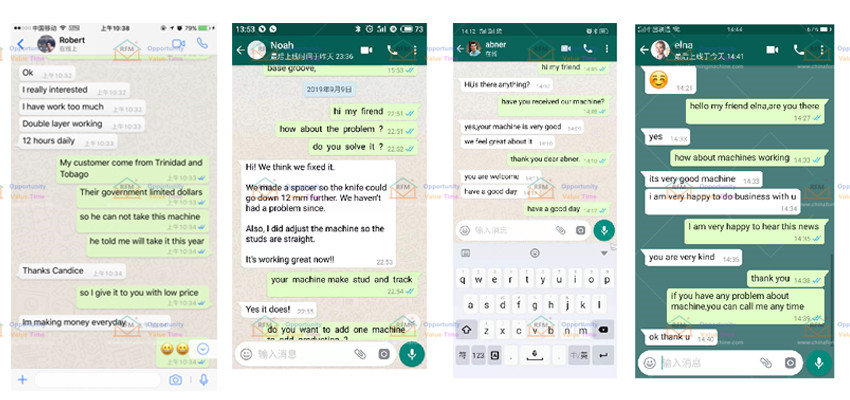

Customer Feedback