This week, I met a Mr. Nick coubary from Australia who is a manufacturer of rolling door curtains. With the expansion of the market, the demand for rolling door curtains has increased and the needs of customers have also diversified. Mr. NIck coubary decided to expand the factory and introduce rolling door curtain forming equipment. He needed an Australian-style rolling door curtain forming machine with simple operation, low noise and automation.

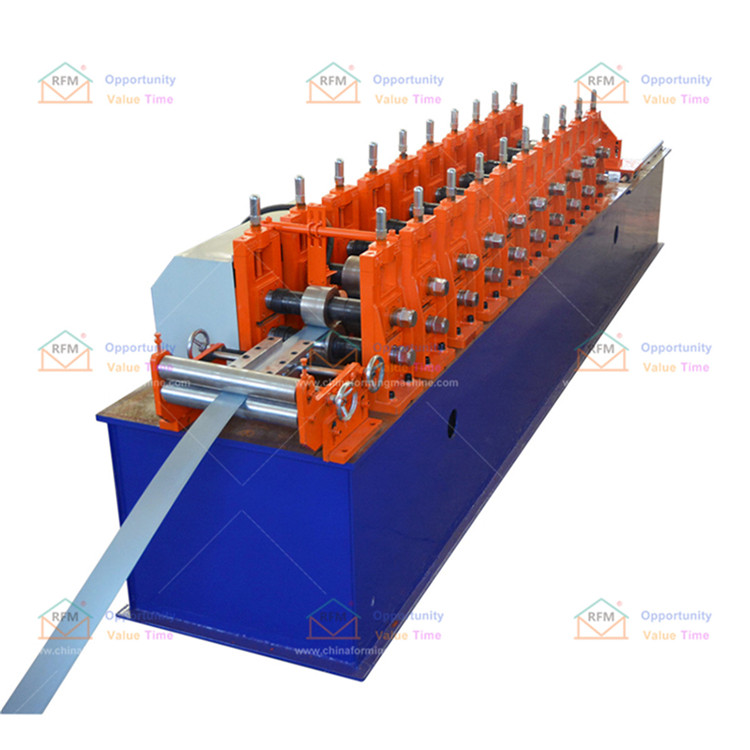

Previously, the equipment purchased by Mr. Nick Coubary had complicated operation, high labor cost, and low production efficiency. The rolling door curtains produced were noisy during installation and use and had a single style. Therefore, we provide customizable Australian-style rolling door curtain forming equipment, which is easy to operate. We also provide on-site commissioning services, and train workers to install, operate, and maintain according to local habits. Solve the problem of low efficiency due to complex operations. The Australian-style rolling door curtain forming equipment adopts a liquid decoiler, which can automatically feed, and the operation of the intelligent randomizer saves labor costs, improves production efficiency, and accelerates the flow of funds for Mr. Nick Coubary and improves economic benefits.

This is a small story I share with you.

Application Range & Scene

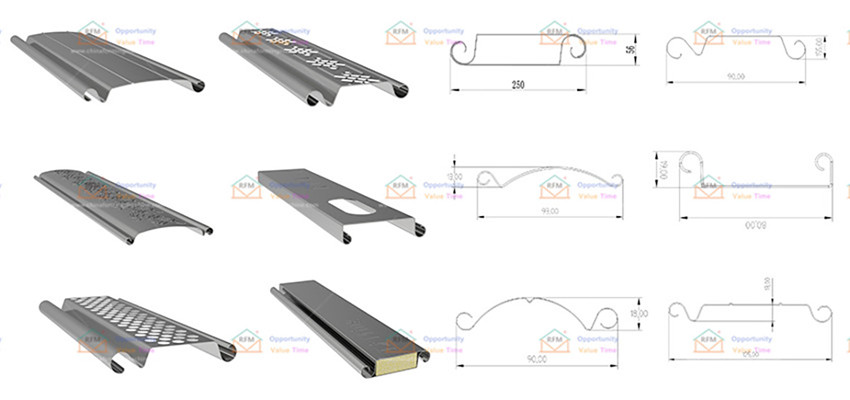

Provide Installation Method & Customized Profile For Free

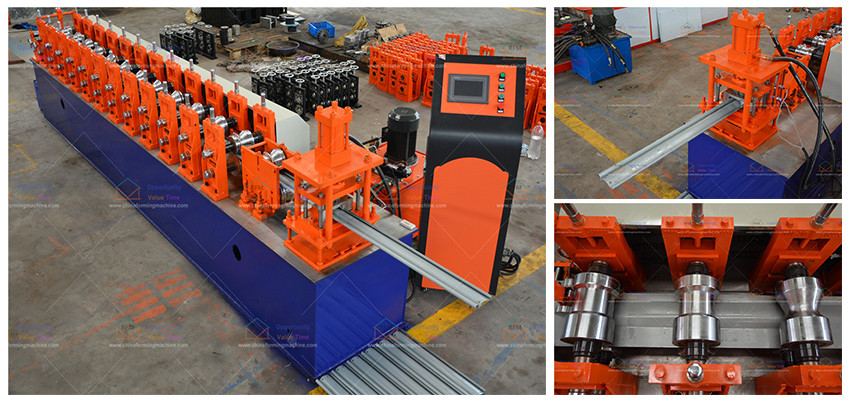

Professional Inspection Process

Customers’ Application Projects

Inspection/Package/Delivery

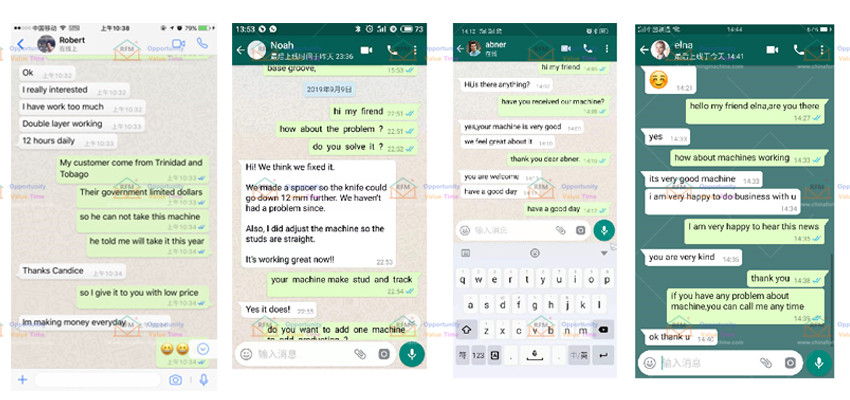

Customer Feedback