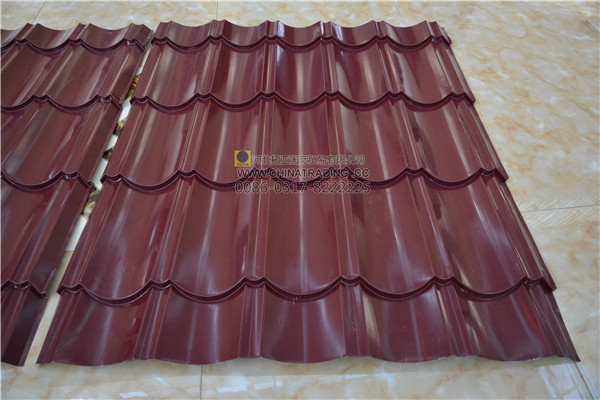

828 Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine production process is not complicated, the production

line equipment can be used automatic production line equipment production, but

also optional part of the mechanical equipment and manual combination of

production, automatic production line equipment, high automation procedures,

requiring less labor. The use of some mechanical equipment and manual

combination of production methods.

Glazed Tile Roll Forming Machine Product Features:

Glazed Tile Roll Forming Machine with high-quality ore raw materials, after screening smash, high pressure

molding, high temperature firing. With high strength, good flatness, low water

absorption, bending, freezing, acid, alkali, never fade, never weathering and

other significant advantages. Widely used in factories, houses, hotels, villas

and other industrial and civil buildings, and its diverse shapes, glazed

rustic, colorful, environmentally friendly, durable, won the architectural

masters of the respected. Western-style glazed tile relative to the traditional

glazed tile, both the following characteristics:

Water resistance: As the Western-style glazed tile surface coated with bright glaze

layer, so that it does not water, no water.

High strength: Western-style glazed tiles are fired at high temperatures, to the

national standard, can withstand more than the body’s weight, and can withstand

the wind and sun for a long time.

Adaptability to various climates: Due to the unique low water absorption characteristics of

Western glazed tiles, it can be used not only in the southern region, but also

in the cold climate of northern China, and keep the color unchanged for long

periods of sunlight.

Adaptation

to Tranquility: Due to the unique craft design of Western-style glazed tiles,

it has a good ability to adapt and reduce the noise, and not long moss, without

artificial care.

Rich

heterosexual accessories: In order to make the roof structure complete and

beautiful, Western-style glazed tile with 14 kinds of unused main tile

accessories, so that the building more artistic atmosphere.

828 Glazed Tile Roll Forming Machine

1

prepared to install Dimensions: 6200mm × 1400mm × 1200mm

2 Total

weight of equipment: about 3600kg

3

Material width: 1000mm, raw material thickness: 0.2-0.8mm

4 forming

pass: 9 Road

5 electronic

control system: the whole machine with industrial computer PLC frequency

control

6 machine

power: 3kw, hydraulic shear power: 3kw

7 Working

speed: 2000mm-3500mm / min

8

hydraulic station pressure: 10-12Mpa

9

pressure tile machine roll material: 45 # steel surface hard chrome plated,

hardness HR55 ° -57 °

10

prepared frame all by 250 # I-beam welding, the plate thickness: 12mm,

11 way: 6

points by the chain drive.

12 Shaft diameter: 70mm

Pls contact with me if you want it.

Address:No

3 Road, Industrial Development Zone, Botou City,Hebei Province, China